1.Preface

Monolithic

tiny switch power supply integrated circuit has the advantages of high integration, high cost performance, the simplest peripheral circuit and the best performance index. It can form an isolated switching power supply without power frequency transformer with high efficiency. From 1994 to 2001, a series of monolithic switching power supply products, such as TOPSwitch, TOPSwitch II, TOPSwitch FX, TOPSwitch GX, TinySwitch, TinySwitch II and so on, have been successively introduced in the world. They have become the preferred integrated circuits for developing medium and small power switching power supply, precision switching power supply and switching power supply modules.

High frequency transformer is an important part of switching power supply for energy storage and transmission. The performance of medium and high frequency transformer in monolithic switching power supply not only has a great influence on power efficiency, but also has a direct bearing on other technical indicators and electromagnetic compatibility (EMC). Therefore, a high efficiency high frequency transformer should have low DC loss and AC loss, low leakage inductance, small distributed capacitance of winding itself and small coupling capacitance between windings. The main points of its design are described below.

2. Reducing Loss of High Frequency Transformer

2.1 DC Loss

DC loss of high frequency transformer is caused by copper loss of coil. In order to improve the efficiency, we should choose the thicker conductor as far as possible, and take the current density J = 4 ~ 10A / mm2.

2.2 AC Loss

AC loss of high frequency transformer is caused by skin effect of high frequency current and loss of magnetic core. High frequency current always tends to flow through the surface when passing through the conductor. This will reduce the effective flow area of the conductor and make the AC equivalent impedance of the conductor much higher than the copper resistance. The penetration ability of high frequency current to conductor is inversely proportional to the square root of switching frequency. In order to reduce AC copper impedance, the conductor radius should not exceed twice the depth of high frequency current. The relationship between the wire diameter and switching frequency is shown in Figure 1. For example, when f = 100kHz, the diameter of conductor is 0.4mm in theory. But in order to reduce the skin effect, the thinner wires can actually be wound side by side, instead of a thick wire.

The core loss of the high frequency transformer also reduces the efficiency of the power supply. The AC flux density of the transformer can be estimated by the following formula:

Bac=(0.4pi*Np*Ip*Krp)/2delta

In formula B: BAC is AC flux density in T;

NP and IP are primary turns and primary peak current respectively.

KRP is the ratio of primary pulsating current to peak current.

Delta is the air gap width of the core in cm.

To design a high frequency transformer working in continuous mode, the typical value of BAC is about 0.04-0.075T. The loss of ferrite core at 100kHz should be less than 50mW/cm3.

3. Reducing Leakage Inductance of High Frequency Transformer

Leakage inductance must be minimized in the design of high frequency transformers. Because the larger the leakage inductance, the higher the peak voltage amplitude, the greater the loss of the drain clamp circuit. This will inevitably lead to lower power efficiency. For a high frequency transformer which meets the insulation and safety standards, its leakage inductance should be 1%-3% of the primary inductance when the secondary circuit is open. In order to reach the target below 1%, it will be difficult to achieve in the manufacturing process. The following measures can be taken to reduce leakage inductance:

1) Reduce turn number NP of primary winding;

2) Increase winding width (e.g. select EE core to increase skeleton width b);

3) Increase the ratio of height to width of windings;

4) Reduce the insulation layer between the windings;

5) Increase the coupling between windings.

3.1 Reduce the number of primary winding turns and increase the ratio of height to width.

The leakage inductance can be effectively reduced by choosing suitable core shape, reducing the number of primary turns and increasing the ratio of height to width. The leakage inductance is proportional to the square of the primary turns. The size of the selected core should be large enough to enable the primary winding to be wound into two or less layers, so that the primary leakage inductance and distributed capacitance can be minimized. Keep in mind that it is not suitable to use the core of a short and fat window because of its large size, small ratio of height to width and large leakage inductance. It corresponds to POT, RM, PQ and some E-type cores. It is suggested to use thin and high core, which has a high aspect ratio and corresponds to EE, ETD, EI and EC cores.

Triple Insulated Wire (Triple Insulated Wire) is a newly developed high performance insulated conductor in recent years. The conductor has three insulating layers, with core wires in the middle. Its insulating layer is golden polyamide film, which is called "gold film" abroad. The total thickness of the insulation layer is only 20 to 100 microns, but it can withstand several kilometers of pulse high voltage. Triple insulated wires are suitable for high frequency transformer windings of micro motor windings and miniaturized switching power supply in the field of advanced technology and national defense. Its advantages are high insulation strength (any two layers can withstand the safe voltage of AC3000V), no barrier layer is needed to ensure safe margin, and no insulating tape layer is used to winding between layers. The volume of the high frequency transformer winded with it can be reduced by half compared with that winded with enameled wire. An optimum design scheme of high frequency transformer is to use ordinary high strength enameled wire to winding primary and feedback stage, and triple insulated wire to winding secondary stage. In this way, the leakage inductance can be greatly reduced, and the volume of high frequency transformer can be reduced by 1/2 to 1/3.

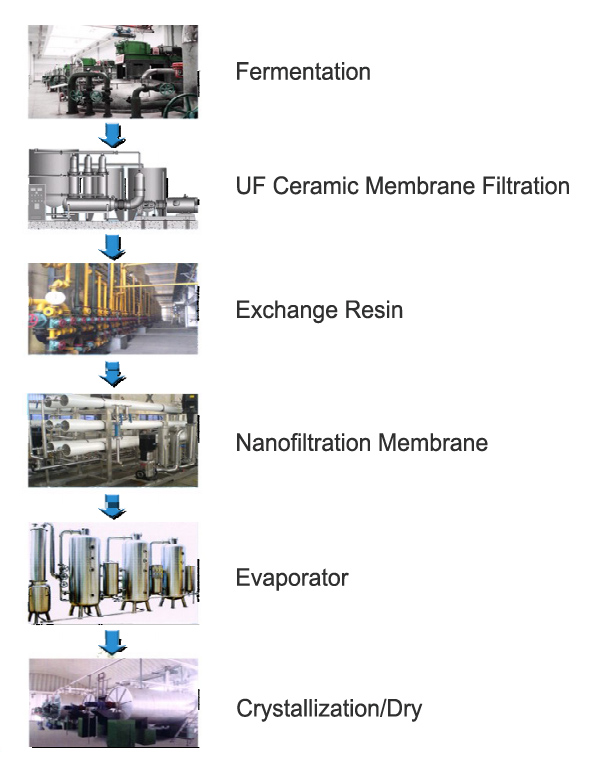

3.2 Winding Arrangement

To reduce leakage inductance, windings should be arranged in concentric manner. As shown in Figure 2, secondary windings in Figure 2 (a) are made of triple insulated wires. In Fig. 2 (b), all enameled wires are wound. However, a safe margin should be set aside and a reinforced insulation layer should be added between the secondary winding and the feedback winding. For

multi-output switching power supply, the secondary winding with the highest output power should be close to the primary winding to increase coupling and reduce magnetic leakage. When the number of secondary turns is very small, in order to increase the coupling with the primary, it is advisable to use multi-strand parallel winding to evenly distribute on the whole skeleton to increase the coverage area. If conditions permit, foil winding as secondary is also a good way to increase coupling.

In the process of switching power supply, the distributed capacitance of winding is charged and discharged repeatedly, and the energy on it is absorbed. Distributed capacitance not only reduces the efficiency of power supply, but also constitutes LC oscillator with distributed inductance of winding, which will produce ringing noise. The effect of distributed capacitance of primary winding is particularly significant. In order to reduce the distributed capacitance, the length of the conductor per turn should be reduced as much as possible, and the initial end of the primary winding should be connected with the drain pole, and a part of the primary winding should be used to shield and reduce the coupling degree of the adjacent windings.

4. Suppressing Audio Noise of High Frequency Transformer

4.1 Suppression of Audio Noise of High Frequency Transformer

The attraction between EE or EI cores of high frequency transformer can displace the two cores. The force of gravity or repulsion between winding currents can also offset the coil. In addition, mechanical vibration can lead to periodic deformation. All these factors will make the high frequency transformer produce audio noise when it works. The audio noise frequency of single-chip switching power supply under 10W is about 10kHz ~ 20kHz.

In order to prevent the relative displacement between magnetic cores, epoxy resin is usually used as binder to bond the three contact surfaces (including the central column) of two magnetic cores. But the effect of this rigid connection is not ideal. Because it can't minimize the audio noise, and there are too many adhesives, the magnetic core is easy to break when it is subjected to mechanical stress. Recently, a special Glassbeads cementing agent has been used abroad to bond ferrite cores such as EE and EI, and the effect is very good. The binder is a mixture of glass beads and adhesives in a ratio of 1:9. It can be cured when it is placed in a temperature environment above 100 C for one hour. Its function is similar to that of ball bearings. After curing, each core can still independently deform or displace in a small range, while the overall position remains unchanged, which has a restraining effect on deformation. The internal structure of high frequency transformer bonded with glass bead adhesive is shown in Fig. 3. This technology can reduce the audio noise by 5 dB.

4.2 Shielding of High Frequency Transformer

In order to prevent the leakage magnetic field of high frequency transformer from interfering with adjacent circuits, a copper sheet can be surrounded outside the transformer to form a shielding band as shown in Fig. 4. The shielding belt is equivalent to a short circuit ring, which can restrain the leakage magnetic field. The shielding belt should be connected to the ground.