Cephalosporin

Cephalosporin is the second class of β-Lactamase found in nature following by penicillin. Any of various broad-spectrum antibiotics, closely related to the penicillins, which were originally derived from the fungus Cephalosporium acremonium. It has many advantages of high efficiency, broad-spectrum, low toxicity and enzyme-resistance which has been developed four new products to its range. It belongs to superior antibiotics that its application is growing widely. Advanced production technique is very pressing to meet brisk demands of the market both domestically and internationally. Cephalosporin C, or simply as CPC, is the source of original nuclear(7-amino cephalosporanic acid)of various cephalosporium antibiotic.

During the production of CPC, frame filter press, rotate vacuum drum filter are still used as a means of separation to remove protein, mycelium, and solid particulates. The technical means available on site did not achieve satisfactory degrees of separation. Meanwhile, those methods are unable to separate the massive existences of soluble protein, macro-molecule organic matters from the broth. The filtered broth shows not high transmittance with residual insolubility and soluble impurities which would increase the difficulty in the downstream extraction process and have a bad effect on the quality and yield of final product. According to market adjusting, some companies are asked to improve separation performance by means of membrane technology and to reduce the product losses. With the wide applications of ceramic membranes, they will play a significant role in separation and purification of antibiotics.

Three steps are introduced in order to guarantee the yield of CPC in the process of filtrate fermentation broth for the production of CPC by ceramic membranes. Pre-concentration step is made to let feed volume Vo concentrate to Vd and permeates are obtained meanwhile; diafiltration step is to add cleaning agents in the wanted liquids while filtration and effective ingredients are got to reach a high yield ; post-concentration step is to concentrate wanted liquids to Ve aiming to treat residuals conveniently and improve yield further.

Ceramic membrane filtration system could intercept protein and solid particulates from the untreated antibiotic fermentation broth. The protein –removing the capability of this technology is 10 times as much as that of the original process, with filtration yield increasing by 6%. The attenuation range of membrane flow rate is narrow and thus a better product quality can be obtained.

The temperature of CPC fermentation broth from the fermented process drops to 10 below zero and it is acidified to pH2.5-3.0 by the use of hydrofluoric acid.

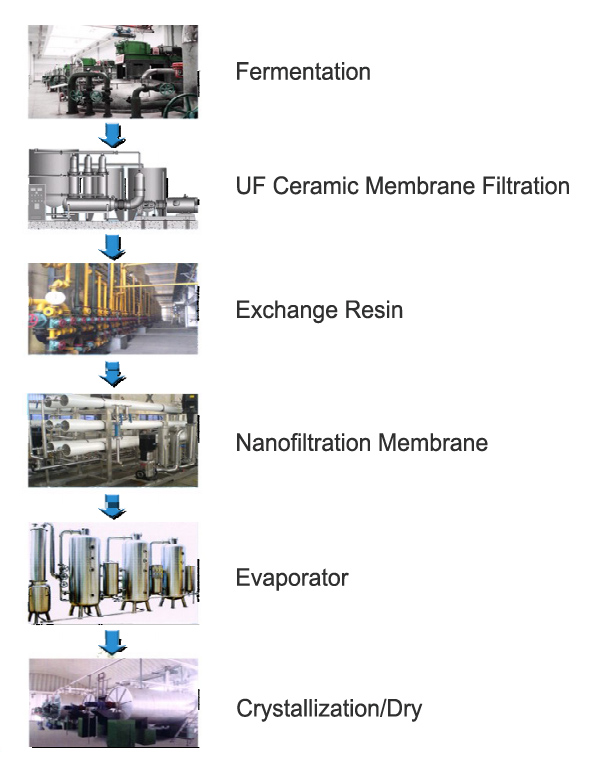

Then CPC clarity is got due to removing mycelium, suspended solids, and macromolecular protein through the filtration process. In the next refining process, macroporous resin adsorption and ion-exchange are applied, and then nanofiltration and reverse osmosis are also used to obtain concentrated CPC.

Process

Spectinomycin

Spectinomycin is an older antibiotic from S. spectabilis whose structure contains an unusual tricyclic ring. Spectinomycin is sold under the tradename Trobicin among others, is an antibiotic useful for the treatment of gonorrhea infections. It is given by injection into a muscle.

In the process of spectinomycin bio-fermentation, there are many bacteria, protein, macromolecular pigment, insoluble starch and sub-micron particles in the fermentation broth. The presence of these impurities can cause blocking in the post-ion exchange adsorption or pollution in the post-extraction, affect the extraction and purification efficiency and lead to the decline of the quality of follow-up products, and even feed contamination, resulting in product scrap, so industrial production must be separated to remove such impurities.

Clarification fermentation broth is usually done by plate frame filtration, vacuum drum filtration, diatomaceous earth filtration, centrifugation, and other methods.

However, neither of these methods can completely and effectively separate the impurities in the fermentation broth, which can easily cause blockage and frequent replacement of the filter medium, thereby affecting work efficiency.

With many years of experience in filtration and membrane separation technology in the pharmaceutical industry, ceramic membrane filtration technology and organic membrane filtration technology are successfully applied to fermentation broth clarification process to solve the problem of clarification in the production of fermentation broth which achieves the goal of simplifying process, convenient operation, clean production requirements and development of advanced scientific and technological innovation.

Erythromycin

Erythromycin is a macrolide antibiotic that has an antimicrobial spectrum similar to or slightly wider than that of penicillin and is often used for people who have an allergy to penicillins.

Erythromycin is mainly fermentation production. As the fermentation broth contains a large number of mycelium, protein and polysaccharide material, to the separation and extraction of erythromycin caused difficulties affecting their yield and quality. Therefore, before the separation and extraction of the fermentation broth need pretreatment. At present, a more commonly used method is flocculation and high-speed centrifuge. The former sterilization rates are relatively high, but the removal of proteins and polysaccharides less effective, resulting in a high solution viscosity, affecting the crystallization process of the follow-up; the latter large energy consumption, equipment is expensive, in the actual production is difficult to wider application.

During the production of erythromycin, frame filter press, rotate vacuum drum filter are still used as a means of separation to remove protein, mycelium, and solid particulates. The technical means available on site did not achieve satisfactory degrees of separation. Meanwhile, those methods are unable to separate the massive existences of soluble protein, macro-molecule organic matters from the broth. The filtered broth shows not high transmittance with residual insolubility and soluble impurities which would increase the difficulty in the downstream extraction process and have a bad effect on the quality and yield of final product. According to market adjusting, some companies are asked to improve separation performance by means of membrane technology and to reduce the product losses. With the wide applications of ceramic membranes, they will play a significant role in separation and purification of antibiotics.

Features of ceramic membrane systems

- Continuous operation mode, allowing continuous feed, permeate and concentration

- Fully automatic control system

- Accurate diafiltration process

- CIP system

- Applicable for filtration at high temperature

- Mechanically strong, highly resistant to wide ranges of pH values, and resistant to acids, caustic, organic solvents and strong oxidants;

- High concentration factor, low water consumption, and small waste discharge

Integrated Ultrafiltration and Nanofiltration is a separation in recent decades developed a new technology, better removal of macromolecules such as proteins and polysaccharides. With this technology, the usage of exacting solvent and de-emulsifier will be greatly minimized, reducing the load on the followed high-speed centrifuge, solvent recycles and treatment of waste solids and wastewater. Moreover, NF permeates could be recycled directly as UF diafiltration water, extensively reducing the consumption of water and the load on wastewater treatment.

Lincomycin

Lincomycin is a lincosamide antibiotic that comes from the actinomycete Streptomyces lincolnensis.

A related compound, clindamycin, is derived from lincomycin by using thionyl chloride to replace the 7-hydroxy group with a chlorine atom with inversion of chirality

Process

- Fermentation pretreatment

- Solvent extraction

- Bleaching

- Crystallization

- Drying

- Final product

Colistin sulphate

Colistin sulphate, also known as polymyxin E, is an antibiotic produced by certain strains of the bacteria Paenibacillus polymyxa. Colistin sulphate is a mixture of the cyclic polypeptides colistin A and B and belongs to the class of polypeptide antibiotics known as polymyxins. Colistin sulphate is effective against most Gram-negative bacilli.

Colistin sulphate Separation and Purification technology is suitable for industrial production of modern antibiotics using microbial synthesis, which can replace traditional purification technologies such as adsorption, precipitation, solvent extraction and ion exchange.

Separation process provides optimum solutions with the unique characteristics without any chemical reaction, no phase change, does not destroy the biological activity, environment-friendly.

CLAVULANIC ACID

Clavulanic acid is a β-lactam drug that functions as a mechanism-based β-lactamase inhibitor.

In the process of clavulanic acid bio-fermentation, there are many bacteria, protein, macromolecular pigment, insoluble starch and sub-micron particles in the fermentation broth. The presence of these impurities can cause blocking in the post-ion exchange adsorption or pollution in the post-extraction, affect the extraction and purification efficiency and lead to the decline of the quality of follow-up products, and even feed contamination, resulting in product scrap, so industrial production must be separated to remove such impurities.

Clarification fermentation broth is usually done by plate frame filtration, vacuum drum filtration, diatomaceous earth filtration, centrifugation and other methods.

However, neither of these methods can completely and effectively separate the impurities in the fermentation broth, which can easily cause blockage and frequent replacement of the filter medium, thereby affecting work efficiency.

With many years of experience in filtration and membrane separation technology in the pharmaceutical industry, ceramic membrane filtration technology and organic membrane utrafiltration technology are successfully applied to fermentation broth clarification process to solve the problem of clarification in the production of fermentation broth which achieves the goal of simplifying process, convenient operation , clean production requirements and development of advanced scientific and technological innovation.