The junction boxes and connectors of photovoltaic modules are small parts that are not noticeable. However, if the quality of these two widgets is not high enough, it will be a huge safety hazard! At present, there should be too many fires in the country due to overheating of connectors, causing huge losses to power stations.

Previously, a well-known foreign agency Fraunhofer ISE and TÜV jointly investigated the fire causes of photovoltaic systems and found that the first and third fire causes were related to the connector.

Failure analysis caused by metal parts

The metal part is the main body of the connector and the most important flow path. When operating in various environments, stable resistance is a prerequisite to ensure the normal operation of the connector.

- Failure analysis of resistor Rco

The resistance Rco is the resistance of the overlapped part of the metal part after the connector is mated. If Rco increases abnormally, it will cause the temperature to rise, which will cause a fire in the middle of the connector.

- Failure analysis of resistor Rcr

The crimping resistance Rcr is mainly related to the crimping quality and crimping process. We can judge the quality of the crimp by the compression ratio and crimp section. Good crimping requires a tight profile without gaps and a regular shape. For commonly used 4mm2 cable crimping and contact resistance at the crimping point, the standard IEC2742 / 05 also puts forward the requirement of less than 0.2mΩ, while IEC60352-2 stipulates that the pull-out force of the crimping end must be greater than 310N.

Failure analysis due to sealing performance

Because the connector is outdoors, it has strict requirements for sealing performance.

For example, some connectors have IP65 and IP68 protection levels. Because the connector is mated to the cable, when it comes to tightness, the choice of cable becomes very important. In general, different connector models correspond to different cable outer diameters, and the purpose is to ensure sealing performance.

For example, the MC4 connector can match photovoltaic cables with an outer diameter of 3-9mm (conductor cross-sectional area of 1.5-10mm2), but its corresponding models are up to 6 types. In order to verify the matching of the cables, after the connectors are assembled, relevant tests are performed, such as IP tests, wet insulation tests, and withstand voltage tests.

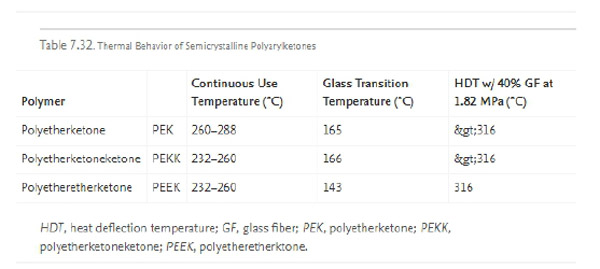

Failure analysis caused by insulation materials

The choice of insulation material directly determines the quality of the connector. A good connector needs to choose the right insulating material, and whether it is suitable is mainly determined by the requirements of the connector, such as weather resistance, heat resistance, flame retardancy, mechanical properties, and insulation properties of the material. Photovoltaic connector insulation The choice of material is the result of comprehensive consideration of these several properties. Choosing the right material can reduce the probability of misfire under high temperature rise.

In addition, it is not possible to use regrind for photovoltaic connectors. The reason for this is because the use of regrind has its extremely strict regulations and product inspection measures. Only in this way can it ensure that the performance of its products does not drop much. The photovoltaic connector is required to be used for more than 25 years in many clients, which means that it has very high requirements for materials.

Although the use of recycled materials can reduce product costs, it increases the probability of product failure at the end of use, so connector manufacturers should eliminate them.

To sum up

Photovoltaic connectors account for a relatively low cost in photovoltaic power plants, but they are a key component. In the early stage of power station construction, the risk of failure caused by the connector is often not taken seriously, but in the later stage it will become a pain point for the operation and maintenance of the power station.

The operation and maintenance costs caused by the failure of the connector include the loss of power generation revenue, the cost of spare parts, labor costs, and safety risks. These operation and maintenance costs will ultimately affect the investment return of the power station. Photovoltaic connectors provided by suppliers with reliable quality and rich experience in production and assembly are one of the foundations to ensure the normal and stable operation of photovoltaic power stations, and the normal operation of power stations is one of the prerequisites to ensure the owners' maximum benefits.

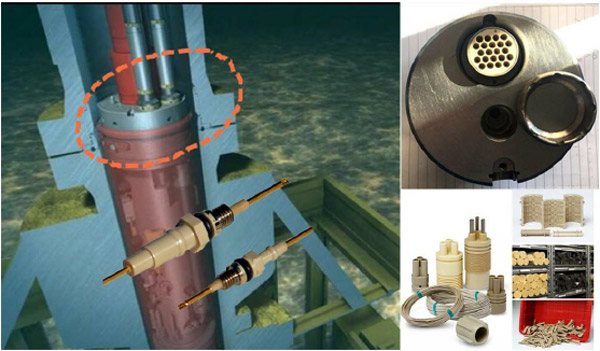

Sunkye is a qualified mil spec military connector manufacturer and supplier, who support custom connectors for a complete range of high-performance applications. A wide variety of military connector options are available to you, feel free to contact us.

Mil spec connector, also called military grade connector or military style connector or military standard connector or military power connector, has been developed to satisfy the market requirements for ultra-tiny size, high performance, great quality, and top qualified customized connector. Sunkye mil grade connector is widely applied for the board to board, system to system, application to application, equipment to equipment. Specially designed for extreme environments like the defense industry, but our mil spec connectors can also be used in a variety of commercial tasks. Our automotive terminal connectors can withstand the harsh conditions of the road and off-road transportation. The combination of Sunkye's mil grade connectors provides reliable solutions for improving the connectivity of critical systems.