Scoliosis is a common health issue that can adversely affect individuals' quality of life and overall health. It can occur in both adolescents and adults, with varying degrees of severity. Scoliosis not only results in abnormal body posture but can also lead to back pain, muscle fatigue, and other health problems.

The importance of spinal and postural screening cannot be overstated. By regularly undergoing spinal and postural screenings, early signs of scoliosis and other issues can be detected, allowing for timely intervention. Early detection and treatment of scoliosis can effectively prevent its progression and alleviate the impact of related symptoms on quality of life.

Spinal and postural screening is crucial not only for individuals already experiencing scoliosis but also for those who have not yet shown obvious spinal issues. Regular postural screening can help individuals maintain good body posture, reduce spinal pressure, and prevent spinal problems from arising.

Significance of Spinal and Postural Screening

Spinal and postural screening plays a significant role in maintaining physical health and preventing scoliosis. With the changing modern lifestyle and the prevalence of sedentary work patterns, spinal issues have become a major health challenge for many people. Therefore, understanding the significance of spinal and postural screening is essential.

Spinal and postural screening helps in the early detection of scoliosis and other related issues. Through regular screening, healthcare professionals can promptly detect signs of abnormal spinal curvature or poor posture. Early detection of scoliosis allows for effective intervention to prevent further progression and reduce adverse impacts.

Furthermore, spinal and postural screening helps prevent the worsening of scoliosis. Timely adoption of correct treatment and management measures upon detection of spinal issues is crucial. Through regular screening, individuals can receive timely treatment and rehabilitation plans, reducing the negative impact of scoliosis on quality of life and preventing more severe consequences.

Regular screening enables individuals to detect signs of spinal issues promptly and take appropriate intervention measures, thereby improving quality of life, reducing pain and discomfort, and achieving comprehensive physical and mental health.

Benefits of Spinal and Postural Screening

Spinal and postural screening is a crucial health practice with benefits covering various aspects, from promoting posture health to enhancing overall quality of life.

Spinal and postural screening helps promote posture health and spinal alignment. Good posture is essential for maintaining the normal curvature and function of the spine. Through regular screening, individuals can assess their posture status and take corresponding measures to adjust poor posture habits. This helps alleviate spinal pressure, improve posture, and thereby prevent spinal issues from arising.

Spinal and postural screening aids in reducing spinal pressure and pain. Poor posture habits and scoliosis can lead to excessive tension and pain in the spine and surrounding muscles. Through regular screening, identifying the root cause of pain, healthcare professionals can devise tailored treatment plans. These plans may include chiropractic spinal adjustments, physical therapy, strengthening exercises, or ergonomic adjustments. Through targeted exercises, stretching, and lifestyle changes, individuals can strive to restore proper alignment, reduce discomfort, and enhance overall spinal function. By addressing underlying spinal issues, individuals can significantly alleviate pain and improve quality of life.

Furthermore, spinal and postural screening contributes to improving physical performance and body function. Good posture and spinal alignment can enhance muscle strength, balance, and flexibility. Through regular screening and appropriate rehabilitation measures, individuals can gradually return to normal physical states, enhancing their quality of life. For individuals engaged in physical activities or professions with high physical demands, spinal posture screening can identify weaknesses, imbalances, or restricted areas that may affect performance. Addressing these limitations through targeted interventions can optimize their spinal function, enhance their athletic performance, and reduce the risk of injury.

Spinal and postural screening helps improve quality of life and overall health. By maintaining good posture and spinal alignment, individuals can reduce pain and discomfort, improve physical function and athletic performance, and enjoy a healthier and more active lifestyle. The phrase "prevention is better than cure" holds true for spinal health. Spinal posture screening can help identify early signs of spinal conditions such as scoliosis, joint degeneration, nerve compression, and muscle imbalance. These conditions can be promptly intervened in the early stages to prevent worsening and potential complications.

Modern Technology and Tools for Spinal and Postural Screening

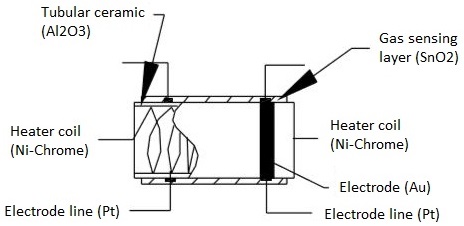

The development of digital spinal and postural screening equipment utilizing advanced sensors and software systems enables real-time monitoring of individuals' posture and spinal curvature, providing objective, quantitative data support. This digital screening process is not only simple and fast but also provides objective, quantitative data support, providing essential references for healthcare professionals to develop personalized treatment plans.

The application of 3D imaging technology in spinal screening is becoming increasingly popular. While traditional X-ray examinations provide static images of spinal structure, they lack comprehensive assessment of posture and dynamic movements. 3D imaging technology can capture individuals' posture and movement states in real time, providing healthcare professionals with more comprehensive and accurate diagnostic information to guide more precise treatment plans.

Furthermore, data analysis and personalized treatment plans are also essential components of modern spinal and postural screening. Through data analysis, healthcare professionals can discover potential patterns and trends in spinal issues, providing guidance for future prevention and treatment. Moreover, a series of personalized treatment plans have been developed to customize the most suitable rehabilitation plan based on individuals' characteristics and needs, maximizing treatment effectiveness and quality of life.

Forethought Medical's Spinal & Postural Screenings Technology

Forethought is dedicated to developing and promoting advanced spinal and postural screening technology, providing high-quality services and solutions for the medical industry and patients. As a leader in the field, Forethought has multiple patented technologies and advanced equipment, providing effective tools and methods for the prevention, diagnosis, and treatment of scoliosis.

Forethought's spinal and postural screening equipment utilizes the latest digital technology to monitor individuals' spinal curvature and posture status in real time. With high-precision sensors and advanced software systems, these devices can accurately analyze various parts of the spine, detect potential issues, and provide timely feedback. This digital screening process is not only simple and fast but also provides objective, quantitative data support, serving as essential references for healthcare professionals to develop personalized treatment plans.

Forethought's spinal and postural screening technology integrates 3D imaging technology, enabling comprehensive assessment of individuals' posture and movement states. Through advanced camera systems and image processing algorithms, this technology can capture three-dimensional images of individuals, displaying changes in spinal curvature and posture and providing dynamic motion analysis. This comprehensive assessment provides healthcare professionals with more comprehensive and accurate diagnostic information, helping them develop more refined treatment plans and improve treatment effectiveness and patient satisfaction.

Forethought emphasizes the research and application of data analysis and personalized treatment plans. Through data analysis, they can discover potential patterns and trends in spinal issues, providing guidance for future scoliosis prevention and treatment. Meanwhile, they have developed a series of personalized treatment plans, tailoring the most suitable rehabilitation plan based on individuals' characteristics and needs, maximizing treatment effectiveness and quality of life.

Forethought's advanced spinal and postural screening technology and tools will inject new vitality into the field of scoliosis, providing patients with better quality and more personalized medical services.