Project Name:Fitness Equipment

Material:ABS

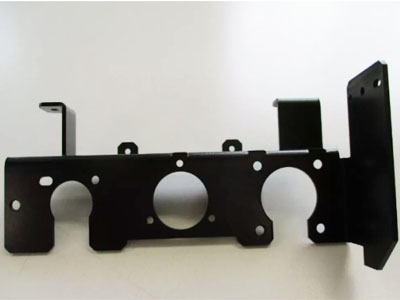

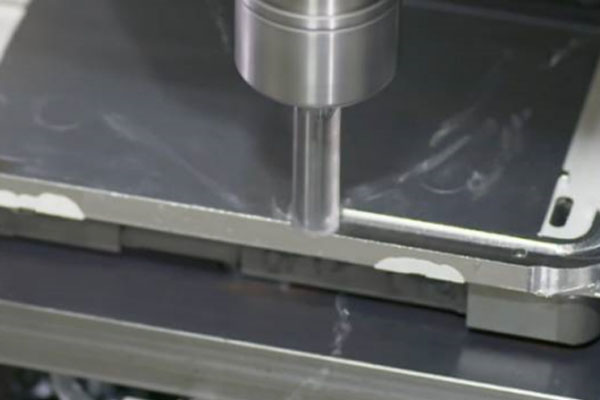

Technology:CNC Machine

Qty:one set

Customer:Australian design company

Advantage:High precision, fast speed and high processing efficiency

Manufacturing Time: 4-5 days

Project Requirements:

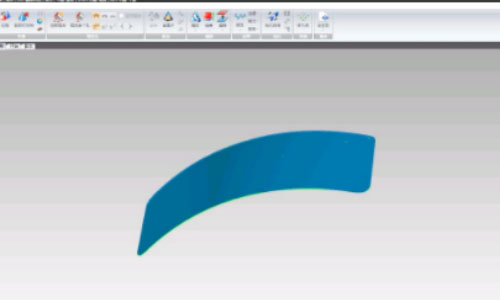

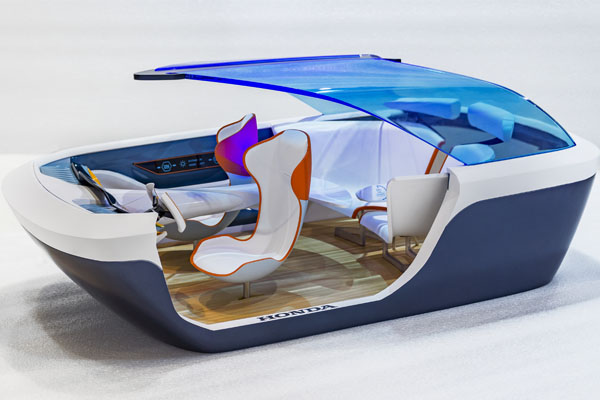

Bright color fitness equipment - with different weights

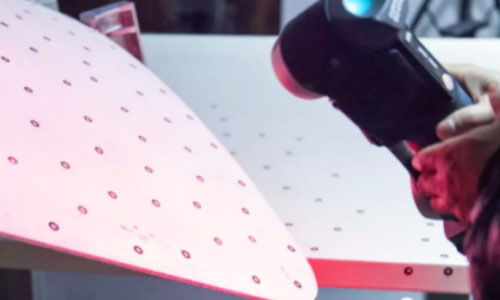

External surface-spray rubber soft touch paint increasing friction

Pre-project analysis:

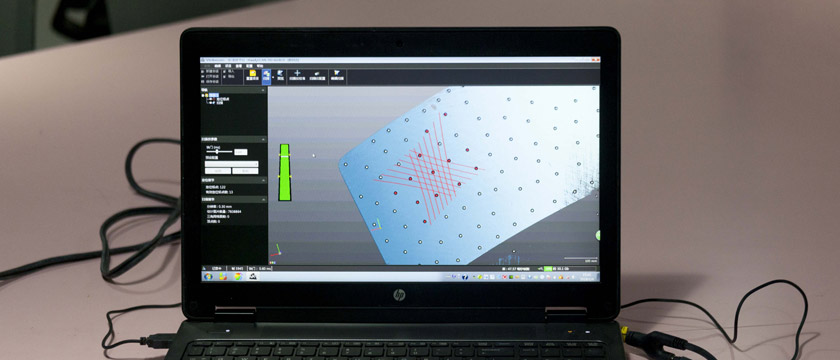

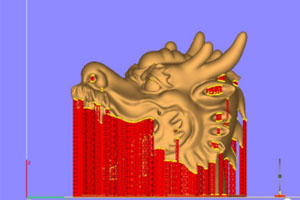

After receiving the design drawings from customer, the production department held a preliminary analysis meeting. Including the pre-analyst, the managers of post-processing department, the spray department and the silk screen department. During this meeting, the various issues that the products need to pay attention to are analyzed in detail. After analysis, it was found that the product was the appearance model, the adhesion of the final product’s rubber paint should be considered.

Process and material selection:

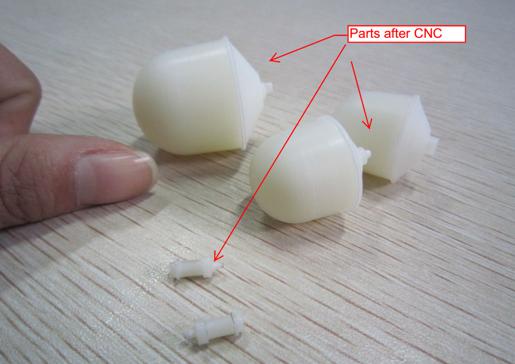

This product's raw material is ABS, and we choose the CNC technology to finish this part. After CNC processing, the model will be polished and painted, and finally a transparent rubber paint is sprayed on the surface.

Production process:

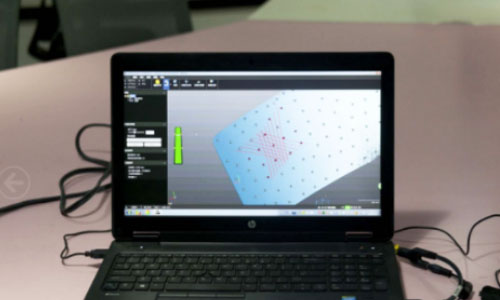

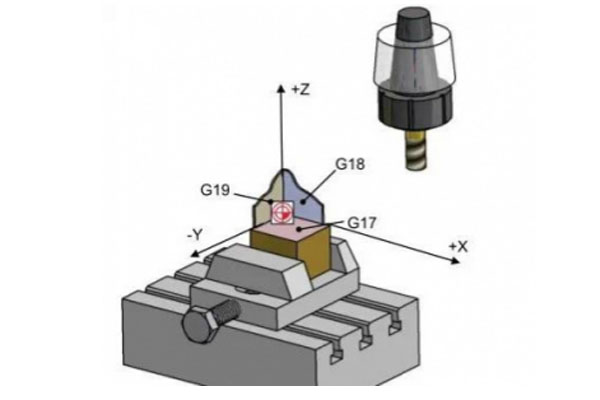

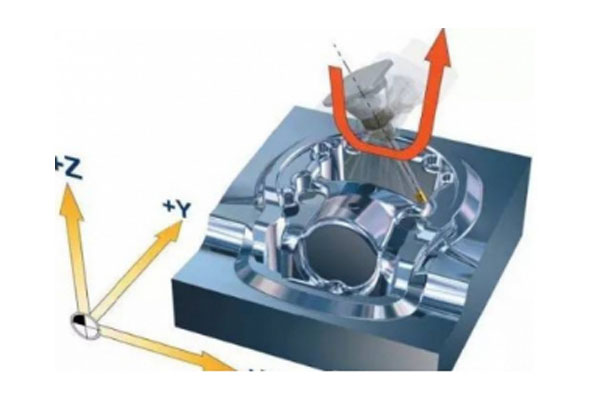

After the analysis and program process, the parts will be arranged CNC machined. In order to ensure all part’s high precision, we prefer the precision machining through the industry-leading CNC equipment.

- Professional post-treatment, the post-treatment of the product focuses on the adhesion of the final product rubber paint. After CNC machining, and polished by our professional post-processing department, the part will be handed over to the spray dept. for painting process. The rubber paint is sprayed on the surface of the product in a matte or semi-matte state. It has a special soft touch and elasticity, friction resistance, impact resistance chemical resistance, good adhesion and durability. After spraying the rubber paint, the adhesion is good, the friction on the surface of the product is increased, and the part's appearance is more beautiful.

Duch Group Provides customers with competitive solutions such as rapid prototyping china, mass production, small batch production, 3D printing, mold making, and injection molding. With more than 20 years of extensive production experience in the rapid prototyping industry, it is one of the world's most professional abs precision machining manufacturers.