Rapid prototyping is a kind of professional manufacturing technology that is used to produce high-quality entity models of three-dimensional designs. Prototypes are useful for design improvements and can be used as stepping stones for comprehensive production or engineering testing. With the plastic rapid prototyping , you can manufacture parts or the products to test for the component fit and function. According to the analysis results, you can make further adjustments (about the design, shape, materials, etc.) before the products finally enter the market. It can help you effectively save time and costs. A lot of our customers need to manufacture a entity component quickly to verify the feasibility of a design or a part. Nowadays, various kinds of rapid prototyping processes are available. You can choose the process which best suits your needs. With only thirty years around of development, rapid prototyping technology, as its name implies, has already been widely used in many areas. Meanwhile, the silicone rapid prototyping services are still growing at a fast speed.

Different Rapid Prototyping Processes

Prototypes can be made through different rapid prototyping processes. With thirty years around of development, a variety of prototype manufacturing processes are available. In addition, they are continuing to evolve. Since companies or customers have different requirements and demands, different types of rapid prototyping processes will be chosen. So how does rapid prototyping work? Reading the following contents and you will know which rapid prototyping service suits you best.

SLA (StereoLithography)

Description: SLA is a photo-curing molding technology, which refers to the method of forming three-dimensional solid layer by layer through the polymerization reaction of liquid photosensitive resin by ultraviolet irradiation. The work piece prepared by SLA has high dimensional accuracy and is the earliest commercial 3D printing technology.

Printing Material: Photosensitive Resin

Strength: photosensitive resin is insufficient in toughness and strength and is easily broken. At the same time, under high temperature conditions, the printed parts are easy to bend and deform, and the bearing capacity is insufficient.

Features of finished product: SLA printed workpieces have good details and smooth surface, which can be colored by spray painting and other processes.

Selective Laser Sintering (SLS)

Description:SLS is a selective laser sintering technology, similar to SLM technology. The difference is the laser power. It is a rapid prototyping method that uses infrared laser as a heat source to sinter powder materials and form three-dimensional parts layer-by-layer.

Printing Material:Nylon powder, PS powder, PP powder, metal powder, ceramic powder, resin sand and coated sand (common printing materials: nylon powder, nylon plus glass fiber)

Strength:material performance is better than ABS products, and the strength and toughness are excellent.

Features of finished product:the finished product has superior mechanical properties and is suitable for direct production of measurement models, functional models and small batch of plastic parts. The disadvantage is that the precision is not high, the surface of the prototype is relatively rough, and it is generally required to be polished by hand, sprayed with glass beads, ash, oil and other post-processing.

Fused Deposition Modeling (FDM)

Description: FDM is a melt lamination technology, that uses high temperature to melt materials, extrudes them into filaments through the print head, and builds up on component platform. FDM is the simplest and most common 3D printing technology, which is commonly used in desktop 3D printing devices.

Printing Material:usually ABS or PLA wire

Strength: PLA is brittle,its surface hardness is higher, and it is easier to break when bending. ABS parts are more resilient than PLA parts, and are easy to bend rather than break under pressure. Moreover, ABS has higher strength, better plasticity, and easier post-processing.

Features of finished product: the printing layer is thick, the precision is poor, and the stratification of the surface is very obvious. Under high temperature conditions, the printed parts are easy to bend and deform, and the bearing capacity is insufficient.

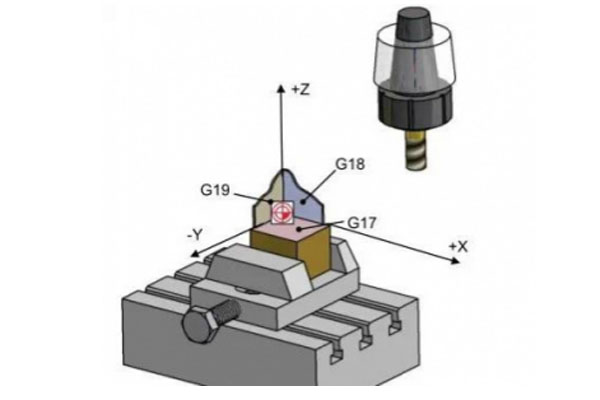

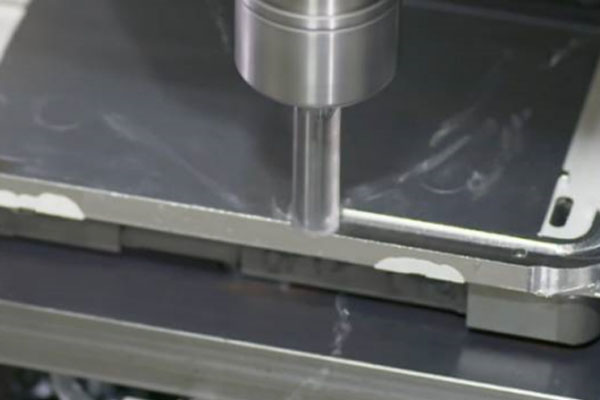

CNC

Description: CNC machining is a subtractive manufacturing process in which the software control system issues instructions to make the tool perform various required movements. In this process, various precision tools are used to remove the raw materials and make parts or products.

Materials: CNC processing materials are quite extensive, including plastics and metals. Plastic hand model materials are: ABS, acrylic, PP, PC, POM, nylon, bakelite, etc.; Metal hand model materials are: aluminum, aluminum Magnesium alloy, aluminum zinc alloy, copper, steel, iron, etc.

Strength: different materials have different strengths and are difficult to list

Features of finished product: CNC machined parts have a smooth surface, high dimensional accuracy, and the best compactness, and there are a variety of post-processing options.

Vacuum Casting

Description: vacuum casting technology is to use the prototype (rapid prototyping parts, CNC hand parts) to make a silicone mold under vacuum condition. It also uses PU, ABS and other materials to pour, so as to clone the same copy with the product prototype.

Material: ABS, PU, PVC, silicone, transparent ABS

Strength: the strength and hardness are lower than the CNC hand parts. Common PU material is relatively brittle, toughness and high temperature resistance are poor. ABS has higher strength, better plasticity, and easier post-processing.

Features of finished product: easy to shrink and deform; the accuracy is generally only 0.2mm. In addition, the vacuum casting hand parts can only resist high temperature of about 60 degrees, and is lower than CNC hand parts in strength and hardness.

Advantages of Rapid Prototyping

High degree of automation in forming process

Precise entity replication

High dimensional accuracy. Dimensional accuracy can be up to±0.1mm

Excellent surface quality

Unlimited design space

No assembly required

Fast forming speed and shorter delivery time

Saving raw materials

Improving product design

Duch Group Provides:

Complete process equipment: we are the only independent manufacturer with large scale in China and can provide both small batch and large batch production services for subtractive manufacturing and additive manufacturing. We have self-developed high-speed intelligent 3D printing equipment, large CNC machining center, vacuum casting machine, low-pressure perfusion and other advanced equipment as well as post-processing production lines such as polishing, painting and so on.

Leading technology: with the latest technology in the world, four world-first 3D printing technology can be diversified, rapid, low-cost, accelerate the research and development speed of enterprise products, and achieve world-class production capacity.

One-stop 3d printing service: 3D printing integrated solution provider, with product development and service output capabilities from equipment, software, materials to cloud printing, can provide global users one-stop service from product design and development to final mass production.

Application of Rapid Prototyping

Shoemaking

3D printing is advancing the revolution of shoemaking industry with the aim of reducing costs, reducing outsourcing, greatly increasing flexibility and preparing for the era of personalized customization and tailoring. Whether through our on-demand production services or our advanced 3D printers, Vistar is happy to participate in this new industrial revolution with our customers.

Medical

It has a high requirement on accuracy and reliability related to the R&D and production of the medical industry. Vistar 3D printing has earned the support and trust from many hospitals and other medical clients through the advantages of on-demand manufacturing service.

Fashion and Cultural Creative

The additive manufacturing provides an entirely new medium for artists that can almost realize any idea. For the fashion designer, Vistar’ production solutions creat an exciting new age which has enabled designers to gain significant on product launches and personalization.

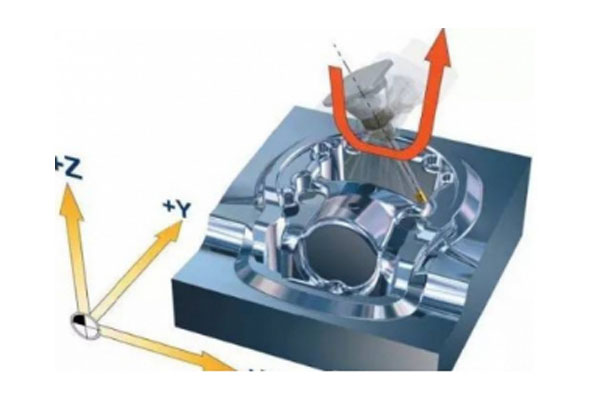

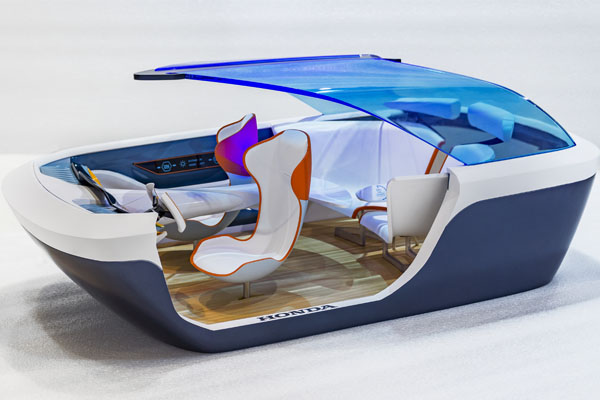

Automobile

The developed at top speed and innovation of the automotive industry is highly compatible with Vistar's manufacturing innovation. 3D printing and related technologies can significantly reduce time to market, as well as make the personalized customization possible.

Dentistry

3D printing technology is becoming more and more mature and popular in the dental market. The total value of dental components manufactured by 3D printing solution exceeded 4 billion US dollars in 2016. The era of digital dentistry is just beginning and Vistar can help you transition easily.

Electronic Product

Diversified electronic industry technology update with a high speed, but Vistar has always been able to adapt to this rhythm and provide customers with required services. Whether it's making new models quickly or making advanced stereo curable 3D printers, you'll be able to make your bold and subtle design more powerful.

Future of Rapid Prototyping

The development of equipment to large-scale

Diversification of Materials development

From the ground to space

Deep space exploration

Benefit thousands of households

Duch Group Provides customers with competitive solutions such as china 3d prototyping , mass production, small batch production, 3D printing, mold making, and injection molding. With more than 20 years of extensive production experience in the rapid prototyping industry, it is the world's largest rapid prototyping service company.