What is 3D Printing Service?

3D printing technology is a collective term for a series of rapid prototyping technologies, the basic principle of which is laminated manufacturing. 3d printing service china providers will use a computer-aided design model to produce a three-dimensional object. 3D printing service includes 3d design and printing services, 3d laser printing services, 3d model printing services, 3d plastic printing services, 3d prototyping service or 3d rapid prototyping services, etc. SLA printing service and SLS printing service are two common types of 3d model printing services.

3D Printing Processes

SLA(StereoLithography)

SLA means laser curing rapid prototyping technology, the process of molding is to dip the photosensitive resin liquid through the workbench, and then irradiate the liquid surface by ultraviolet light, and the irradiated part is immediately solidified and formed. After the layer is formed, the workbench is lowered. The height of the layer, the liquid surface is re-impregnated through the workbench, and the ultraviolet light is subjected to curing irradiation of the next layer, so that the layer is solidified and formed to obtain a three-dimensional solid prototype.

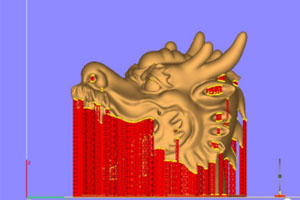

SLA Processes:

1. Created by 3D modeling software, the 3D model of the 12 animal heads is produced, and the stl format is derived.

2. Import the file into Magics software for slicing.

3. Import the processed 3D files into the ProtoFab SLA light-curing 3D printer for 3D printing and curing.

4. Post-treatment process of 12 animal head models by cleaning, polishing etc.

5. Painting the polished animal head model.

SLM (Selective Laser Melting)

SLM represents elective laser melting, a kind of additive manufacturing, metal powder rapid prototyping technology, which can directly form metal parts that are close to full density and good mechanical properties. SLM technology overcomes the complicated process of manufacturing metal parts by Selective Laser Sintering (SLS) technology.

The SLM technology is a technique in which metal powder is completely melted by the heat of a laser beam and solidified by cooling.

3D Printing Materials

Resins: photosensitive resin, transparent resin, translucent resin, high-precision resin, high temperature resistant resin, high toughness resin, soft rubber, etc.

Nylon: nylon + glass fiber, nylon + carbon fiber, etc.;

Metals: mold steel, stainless steel, aluminum alloy, titanium alloy, copper alloy, etc.;

We offer a variety of post-processing methods ,such as paint, silk screen, water transfer, polishing, sand blasting, electroplating, vacuum plating and so on.

3D Printing Applicaitons

3D printing is involved in the jewellery, footwear, industrial design, construction, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms and other fields. Namely, 3D printing can be used in the entire industrial sector.

We are a Professional Reaction Injection Molding Manufacturer

We are one of the leading 3d prototyping companies in the world, providing cheap 3d printing service and creative products to a new era of personalized customization. We use the world's leading 3D printing technology, the world's largest SLA 3D printing molding equipment (maximum molding size of 2.4 meters), which can quickly convert your 3D data into physical, unstructured, industrial-grade high-precision 3D printing and ensure product dimensional accurac. Here you can find the rapid prototyping services you need for your project.

We have established many printing bases around the world. We have three printing bases in China (Xiamen, Suzhou, Chongqing) and nine production bases abroad (Norway, South Korea, Los Angeles, Germany, UK, Russia, Italy, France, Munich, Turkey) ). We plan to constructe the largest 3D printing public service platform and customized intelligent manufacturing cloud platform in China and the world, providing custom 3D printing services to users around the world, ensuring the production efficiency of hand prototypes to ensure that products are delivered on time.

If you are looking for professional and reliable 3d prototyping companies, please contact our professional team at info@duchgroup.com or contact us using the inquiry form on this website, we will provide quotes and suggestions free of charge.