JIUWU company produces the ceramic ultrafiltration membranes with the pore size 20nm, 50nm and so on. JIUWU company offers a large choice of ceramic uf membranes with different geometries and cut-offs to meet your process requirements in viscosity, molecule size, impurity profile, purity and yield target, etc. as well as cleaning and sanitization procedures. Ceramic ultrafiltration membranes are better than those membranes in ceramic membrane filtration systems. Our UF membrane water filter won't let you down!

OVER VIEW OF ULTRAFILTRATION CERAMIC MEMBRANE ELEMENT

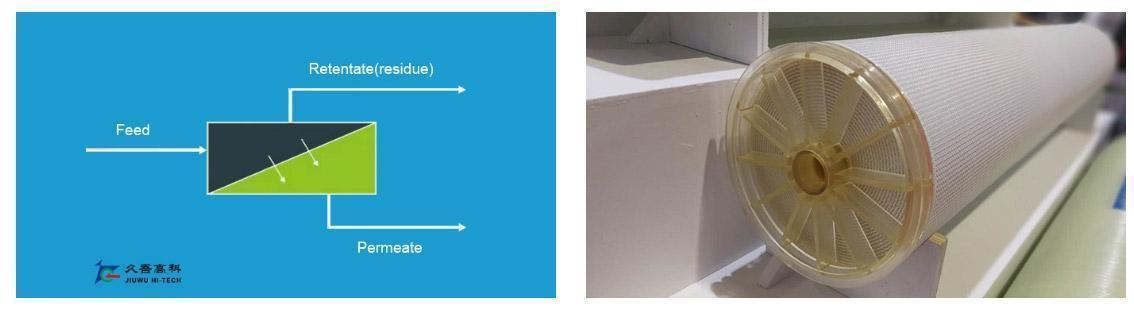

Ultrafiltration ceramic membrane/ceramic filter is a variety of membrane filtration in which forces, such as pressure or concentration gradients, cause separation through the semi-permeable membrane. High molecular weight suspended solids and solutes remain in the so-called retentate while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). The pore size of the ultrafiltration ceramic membrane is in the range of 0.01μm ~ 0.05μm, suitable for the separation, concentration, and purification of macromolecules and small molecules.

A versatile and economical solution for clarification, concentration, and purification of liquids, ultrafiltration membrane filter could remove emulsified oils, metal hydroxides, colloids, bacteria and viruses, emulsions, dispersed material, suspended solids, and other large molecular weight materials from water and other solutions. Ultrafiltration ceramic membrane also serves in critical parts of the production processes of fruit juice, milk and whey, electrocoat paints, pharmaceuticals, poly-vinyl alcohol, and indigo dye. It is key to surface water treatment for potable uses and wastewater treatment for reuse, such as palm oil wastewater and paper mill wastewater treatment. Ultrafiltration ceramic membrane is used to recycle flow or add value to later products and more. In many cases, ultrafiltration ceramic membrane is used for prefiltration in reverse-osmosis plants to protect the reverse-osmosis process. Ultrafiltration ceramic membrane is an effective means of reducing the silt density index of water and removing particulates that can foul reverse osmosis membranes.

APPLICATION OF ULTRAFILTRATION CERAMIC MEMBRANE ELEMENT

Food & beverage

Bio-pharm

Chemical and petro-chemical

Water & wastewater treatment

ADVANTAGE OF ULTRAFILTRATION CERAMIC MEMBRANE ELEMENT

High flux

Reliability

Well-proven long operating life

Ease of use, clean, regenerate

Stable over a wide pH (0-14) range and chemical compatibility

Sterilization by steam and oxidizing agents

Wear ability and excellent strength

Narrow pore size distribution

Stringent quality control process and procedures with full trace ability

Excellent performance in MF/UF & thermal stability

To know more information about uf membrane filter price and microfiltration membrane price, please feel free to contact us!