In addition to being widely used in terminal ports and transport containers, semi-trailers also have a series of models suitable for transporting dry goods, bulk cargo, timber, etc. on the road. What types of bulk semi trailer does Ultraton have? With these years' rich manufacturing experience and feedback from customers, the main types of Bulk Cargo Semi Trailer we Ultraton produce are Fence Semi Trailer, Side Wall Semi Trailer, Low Bed Semi Trailer. They are the most commonly used on market and popular among those Bulk Cargo Semi Trailer on sale. Bulk Cargo Semi Trailer can also be customized according to customer requirements, to provide you with a specific Bulk Cargo Semi Trailer for your business. If you need to transport bag package grain, feed, vegetable, etc., Side Wall Semi Trailer could be a good choice.

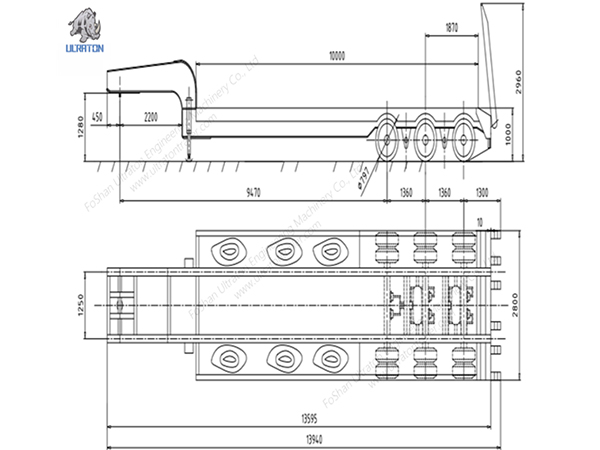

If you need to transport livestock, bottle beverage, and general stuff, Fence Semi Trailer could be your good partner. They are usually modified based on Flatbed type, by adding stakes or boards. On this, Ultraton semi truck trailer manufacturers has mature workmanship and skilled technique to ensure reasonable structure, flexible design, wonderful space effect, reliable braking. Its structure is similar to Van but due to its more flexible loading capacity, lighter tare weight, this type of Bulk Cargo Semi Trailer could be more convenient, practical and safe. What difference between Fence Semi Trailer and Side Wall Semi Trailer? Its main difference comes from the height and structure of fence. As for low Bed Semi Trailer, it is one kind of Flat Bed Semi Trailer and more suitable to transport heavy duty equipment for its lower center of gravity. Low Bed Semi Trailer could be more flexible to be modified for heavy duty purpose. High tensile steel designed main I beam and durable stable structure is base. Floor in thick hard wood or checker plate steel is optional. As enhancement, Mechanical or hydraulic rear ramps, removable goose neck and more also could be designed into Low Bed Semi Trailer for a greater performance.

Bulk Cargo Semi Trailer can also be customized according to customer requirements, to provide you with a specific Bulk Cargo Semi Trailer for your business. If you need to transport bag package grain, feed, vegetable etc., Side Wall Semi Trailer could be good choice. If you need to transport livestock, bottle beverage, and general stuff, Fence Semi Trailer could be your good partner. They are usually modified based on Flatbed type, by adding stakes or boards. On this, Ultraton has mature workmanship and skilled technique to ensure reasonable structure, flexible design, wonderful space effect, reliable braking. Its structure is similar to Van but due to its more flexible loading capacity, lighter tare weight, this type of Bulk Cargo Semi Trailer could be more convenient, practical and safe. What difference between Fence Semi Trailer and Side Wall Semi Trailer? Its main difference comes from the height and structure of fence. As for low Bed Semi Trailer, it is one kind of Flat Bed Semi Trailer and more suitable to transport heavy duty equipment for its lower center of gravity. Low Bed Semi Trailer could be more flexible to be modified for heavy duty purpose. High tensile steel designed main I beam and durable stable structure is base. Floor in thick hard wood or checker plate steel is optional. As enhancement, Mechanical or hydraulic rear ramps, removable goose neck and more also could be designed into Low Bed Semi Trailer for a greater performance.