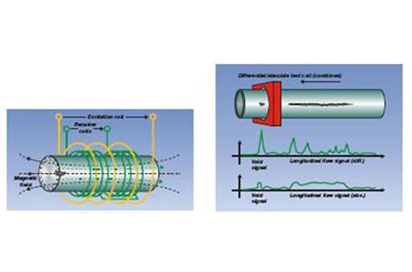

Ultrasound flaw detection is a method to inspect the defect of a part by means of the reflection characteristics of the interface edge when the ultrasonic energy penetrates into the depth of the metal material and one section enters another section. When the ultrasonic beam passes from the surface of the part to the inside of the metal from the probe, the reflected waves will occur separately when the defect and the bottom of the part are encountered. Pulse waveforms are formed on the fluorescent screen, and the position and size of defects are judged according to these pulse waveforms. Eddy current detection is to use the principle of electromagnetic induction to excite the probe coil with the sinusoidal current. When the probe approaches the metal surface, the alternating magnetic field around the coil generates induced current on the metal surface. For flat metal, the flow direction of the induced current is a circle with concentric coils, similar to a vortex, called eddy current. At the same time, the eddy current also produces the same frequency magnetic field, which is opposite to the coil magnetic field.

The loss resistance of the eddy current channel and the reverse flux produced by the eddy current are reflected in the probe coil, which changes the current size and phase of the coil, that is, the impedance of the coil. Therefore, when the probe moves on the metal surface and encounters defects or changes in material and size, the eddy current magnetic field reacts differently to the coil, causing the coil impedance to change. By measuring the variation with the eddy current testing instrument, the defect on the metal surface or other changes in physical properties can be identified.

There are many factors affecting the eddy current field, such as the coupling degree between the probe coil and the tested material, the shape and size of the material, conductivity, permeability, and defects, etc. Therefore, the eddy current principle can be used to solve the problems of metal material flaw detection, thickness measurement and sorting.

We did eddy current vs ultrasonic testing,eddy current testing and we mastered ultrasonic flaw detector theory,ultrasonic flaw detector working principle and pulsed eddy current principle,so our products like ndt machine,which can be guaranteed.