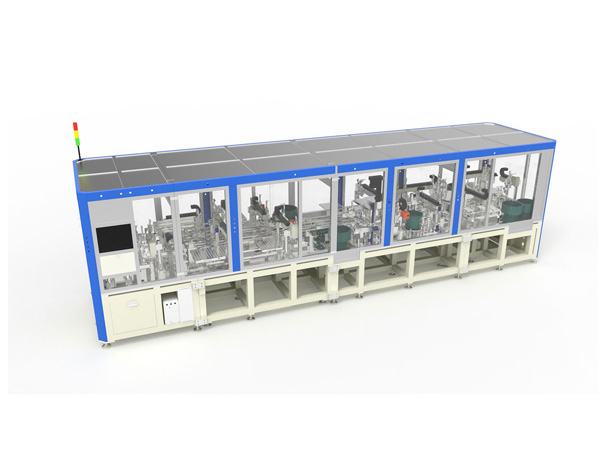

The China automatic production line completes bolt assembly, detection, laser marking, data recording and other requirements, which is composed of spring base press-fitting station, valve sleeve assembly station, spring and valve core assembly station, laser marking, thread detection and traceable system, etc. The parts are conveyed to the corresponding positions by conveyor and turntable. The manipulator grabs the materials to assembly and the human-machine control system / automation assembly line production line corrects the parameters of the assembly process and records the data.

Machine Features of Central Bolt Assembly Line Automation Equipment

1.Frame: The safety guard door frame uses aluminum alloy profiles

2. Machine parts: Chrome-faced, anodizing, black and paint baked

3. Noisy:≤70dB

4. Security Settings: The HMI can set a password to prevent non-professionals from mishandling the machine or other potential safety hazards.

Machine parameter of Central Bolt Automatic Production Line

FL14.0002.01

Power: AC380V

Floor space: 3650*2800*1800(L*W*H)

Station: 1

Power: 20KW

Continuous activation ratio:>=90%

Pass rate:>=99%

Weight:3.5t

Comments