Why Need A Color Sorter During Granulation?

In the production of plastic granules, the production of the granules of the former color is completed, usually without stopping the machine, and the next granule is produced immediately. This causes a situation in which granules of two colors are mixed together, and if they are not processed, waste is formed.

The use of plastic granule color sorter to separate granules of different colors can avoid this situation and increase value.

LINPRO Special Technology of Mixed Plastic Granule Color Sorter

- The system includes lighting system, image acquisition unit, processing unit, and execution unit, which is implemented based on machine vision technology. Besides, field experiment was performed. The result reveals that the system has a high accuracy of measurement and a fast response speed.

- Automatic cleaning system can be set according to your need.

- Low power consumption, save the production cost.

- One set color sorting machine can work for different plastic material: such as PP PE, HDPE, LDPE etc.

- User-friendly intelligent interface, easy to operate and easy to maintain.

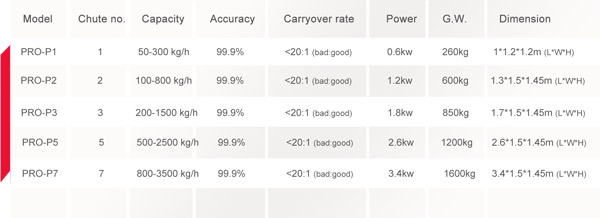

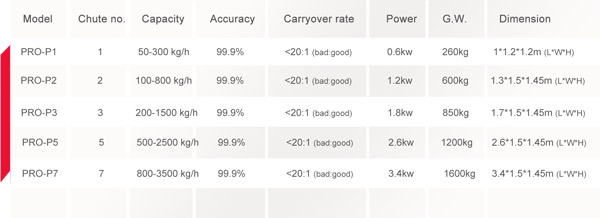

About capacity of Mixed Plastic Granule Color Sorter

There are different size machines available for choosing.

Voltage: 220V/50HZ or 60HZ

Welcome to contact us for best suggestion!

LINPRO technology support and service

- We will send an engineer to install machine well in local factory, and running machine well.

- Our engineer will give professional training for customers’

- 24 hours engineer consultation service on line during machine running time.

- 1 year warranty provided.

- Software updated to follow LINPRO color sorter technology.

We aim to provide every customer our VIP service, welcome to contact us for inquiry or any questions !