Introduction to Non-Wetting in Soldering

Non-wetting in soldering is a common defect in electronics manufacturing where molten solder fails to properly adhere to the surface of a component or substrate. This issue compromises the integrity of solder joints, affecting the reliability and performance of electronic devices.

Understanding non-wetting in soldering is essential for manufacturers aiming to produce high-quality semiconductor devices and power electronics, such as those developed by companies like Chengliankaida Technology Co., Ltd. This article explores the causes, impacts, and solutions for non-wetting, with a focus on advanced soldering technologies.

What Causes Non-Wetting in Soldering?

Surface Contamination

One of the primary causes of non-wetting in soldering is surface contamination. Contaminants such as oxides, oils, or residues on the component or substrate surface prevent the solder from forming a strong metallurgical bond. Oxidation, in particular, creates a barrier that inhibits the solder’s ability to wet the surface effectively, leading to incomplete or weak joints.

Improper Flux Application

Flux plays a critical role in removing oxides and promoting solder wetting. However, insufficient or incorrect flux application can result in non-wetting in soldering. If the flux is not active enough or is applied unevenly, it fails to clean the surface adequately, causing poor adhesion of the solder.

Material Incompatibility

Non-wetting in soldering can also occur due to incompatible materials. For instance, certain metal surfaces, such as aluminum or stainless steel, are inherently difficult to solder without specialized fluxes or surface treatments. Mismatched solder alloys and substrate materials can further exacerbate non-wetting issues.

Inadequate Heating

Proper heating is essential for achieving good wetting in soldering. If the soldering temperature is too low, the solder may not reach its optimal flow state, leading to non-wetting in soldering. Conversely, excessive heat can degrade the flux or damage components, also contributing to poor wetting.

Impacts of Non-Wetting in Soldering

Reduced Joint Reliability

Non-wetting in soldering results in weak or incomplete solder joints, which compromise the mechanical and electrical reliability of electronic assemblies. These defective joints are prone to cracking or failing under thermal or mechanical stress, leading to device malfunctions.

Increased Void Formation

Voids—gas pockets within the solder joint—are often associated with non-wetting in soldering. These voids reduce the thermal and electrical conductivity of the joint, potentially causing overheating or signal integrity issues in high-power devices like IGBT modules or diodes.

Higher Production Costs

Non-wetting in soldering can lead to increased rework and scrap rates, driving up production costs. Manufacturers may need to invest in additional quality control measures or repair processes to address defective solder joints, impacting overall efficiency.

Solutions to Prevent Non-Wetting in Soldering

Surface Preparation and Cleaning

Effective surface preparation is crucial for preventing non-wetting in soldering. Cleaning components and substrates to remove contaminants like oxides, grease, or dust ensures better solder adhesion. Techniques such as plasma cleaning or ultrasonic cleaning can significantly improve surface wettability.

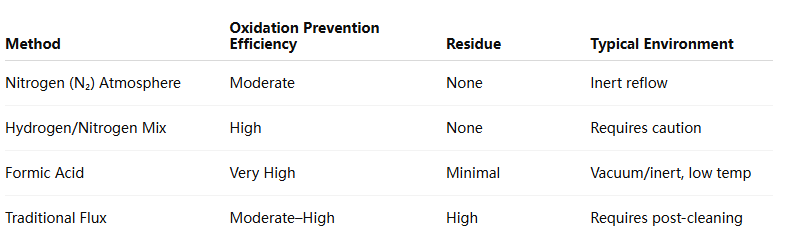

Optimizing Flux Selection and Application

Choosing the right flux and applying it correctly can mitigate non-wetting in soldering. Fluxes with higher activity levels are better suited for challenging surfaces, while precise application ensures uniform coverage. Manufacturers should also ensure that flux residues are properly cleaned post-soldering to avoid corrosion.

Advanced Soldering Technologies

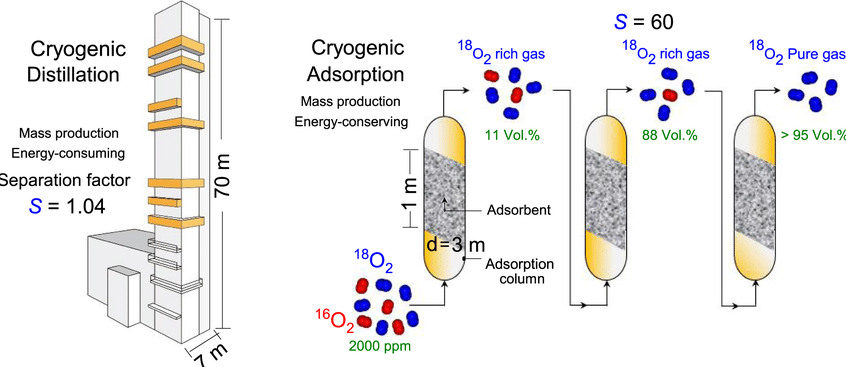

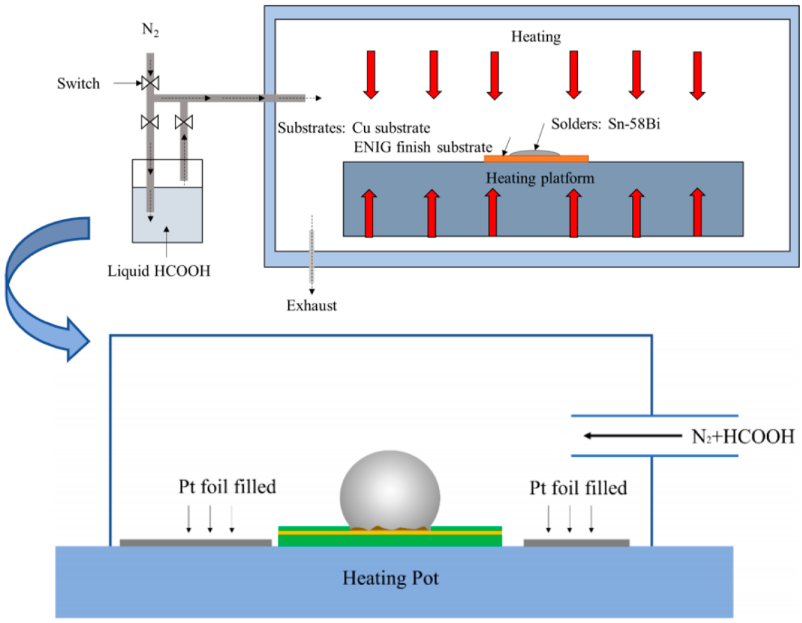

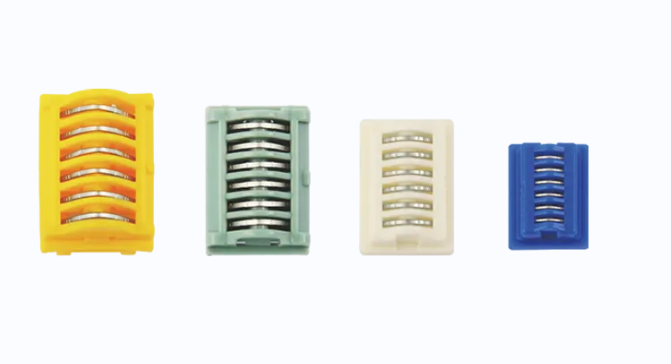

Modern soldering technologies, such as vacuum soldering systems, offer effective solutions for addressing non-wetting in soldering. By soldering in a controlled, low-oxygen environment, these systems minimize oxidation and promote uniform wetting. For example, the Vacuum Reflow Soldering Oven is designed to create void-free solder joints, ensuring high reliability for semiconductor and power device packaging.

Another advanced solution is the Formic Acid Vacuum Reflow Oven, which uses formic acid to enhance surface cleaning during the soldering process. This technology reduces oxides and improves wetting, making it ideal for applications requiring hermetic sealing and low void rates.

Controlling Soldering Parameters

Precise control of soldering parameters, such as temperature, time, and atmosphere, is critical for preventing non-wetting in soldering. Automated systems with real-time monitoring can maintain optimal conditions, ensuring consistent solder flow and adhesion.

Role of Vacuum Soldering in Addressing Non-Wetting

Benefits of Vacuum Soldering Systems

Vacuum soldering systems are highly effective in combating non-wetting in soldering. By removing air and reducing oxygen levels, these systems prevent oxide formation during the soldering process. This leads to cleaner surfaces and stronger metallurgical bonds, significantly reducing non-wetting issues.

Applications in Power Electronics

In power electronics, such as IGBT modules and diodes, non-wetting in soldering can lead to catastrophic failures due to the high currents and temperatures involved. Vacuum soldering systems, like the Vacuum Reflow Soldering Oven, ensure void-free joints, enhancing thermal conductivity and device longevity.

Formic Acid for Enhanced Wetting

The use of formic acid in vacuum soldering, as seen in the Formic Acid Vacuum Reflow Oven, further improves wetting by chemically reducing oxides on the surface. This approach is particularly effective for complex assemblies requiring high reliability and hermetic sealing.

Best Practices for Minimizing Non-Wetting in Soldering

Process Optimization

Manufacturers should implement robust process controls to minimize non-wetting in soldering. This includes regular calibration of equipment, monitoring of solder bath conditions, and adherence to standardized procedures.

Training and Quality Assurance

Skilled operators and rigorous quality assurance protocols are essential for identifying and addressing non-wetting in soldering early in the production process. Training programs should emphasize proper handling of materials and equipment to prevent defects.

Material Selection

Choosing compatible solder alloys, fluxes, and substrates can significantly reduce non-wetting in soldering. Manufacturers should conduct thorough material compatibility tests to ensure optimal performance.

Future Trends in Soldering Technology

Advancements in Vacuum Soldering

The ongoing development of vacuum soldering technologies continues to address non-wetting in soldering. Innovations like inline vacuum soldering systems and multi-chamber ovens are improving throughput and consistency, making them suitable for high-volume production.

Integration with Automation

Automation and real-time monitoring are becoming integral to soldering processes. These advancements enable precise control of soldering parameters, reducing the likelihood of non-wetting in soldering and improving overall yield.

Eco-Friendly Soldering Solutions

As environmental regulations tighten, manufacturers are exploring eco-friendly fluxes and lead-free solders to prevent non-wetting in soldering while meeting sustainability goals. These materials require careful selection to ensure compatibility and performance.

Conclusion

Non-wetting in soldering is a critical challenge in electronics manufacturing, leading to unreliable solder joints and increased production costs. By understanding its causes—such as surface contamination, improper flux application, and inadequate heating—manufacturers can implement effective solutions like advanced vacuum soldering systems. Technologies like the Vacuum Reflow Soldering Oven and Formic Acid Vacuum Reflow Oven play a pivotal role in achieving void-free, high-quality solder joints. Through proper surface preparation, optimized processes, and innovative equipment, non-wetting in soldering can be minimized, ensuring reliable and efficient production of electronic devices.