What Is Selective Wave Soldering and Why Is It Used?

Selective wave soldering is a technique designed for soldering through-hole components on PCBs, especially those that also contain surface-mount devices (SMDs). Unlike traditional wave soldering that immerses the entire board, selective wave soldering precisely targets specific areas using mini-waves or solder nozzles.

Key Advantages of Selective Wave Soldering:

Reduces thermal stress on components

Minimizes solder bridges and defects

Enhances process control and repeatability

Suitable for high-mix low-volume production

However, oxidation of pad surfaces and leads during the soldering process remains a major reliability concern.

Why Is Oxidation a Problem in Selective Wave Soldering?

Oxidation occurs when metal surfaces are exposed to oxygen at high temperatures. In soldering, it leads to:

Poor wetting

Increased solder defects (e.g., non-wetting, dewetting)

Weakened mechanical joints

Higher rework rates and reduced production yield

As selective wave processes often involve localized heating, any delay between flux activation and solder contact can exacerbate oxidation, especially in lead-free environments.

Which Gas Is Commonly Used to Prevent Oxidation in Selective Wave Soldering?

The Answer: Nitrogen (N₂)

Nitrogen is the most widely used inert gas in selective wave soldering. Here's why:

Inert Atmosphere: Displaces oxygen around the solder nozzle

Stable Solder Temperature: Improves wetting behavior

Flux Efficiency: Reduces flux oxidation and preserves activity

Solder Joint Quality: Produces cleaner and stronger joints

Process Consistency: Enables repeatable and reliable results

Typical Purity Used: 99.99%

Flow Rate: 10–25 L/min per nozzle (varies by equipment)

How Is Nitrogen Applied in the Selective Wave Process?

Nitrogen is introduced into the soldering area using one or more of the following methods:

Nozzle Shrouding: Nitrogen surrounds the mini-wave nozzle directly.

Preheating Chamber Atmosphere: Reduces early-stage oxidation.

Enclosed Mini Wave Module: Maintains controlled environment throughout the soldering zone.

Modern selective wave systems are often equipped with nitrogen gas monitoring and flow control systems for optimal consumption and protection.

What Are the Alternatives to Nitrogen in Selective Soldering?

While nitrogen is dominant, other gases may be used in specific systems:

Formic Acid (HCOOH)

Used in Formic Acid Vacuum Reflow Oven, this reducing gas actively removes oxides, especially in fluxless soldering processes for semiconductors and power devices.

Pros:

Cons:

Formic acid is not typically used in selective wave processes due to open system architecture, but it's key in high-end vacuum soldering systems.

What Role Does Nitrogen Play in Advanced Vacuum Soldering Equipment?

While selective wave soldering often uses open systems with nitrogen shrouding, vacuum-based systems like

Vacuum Reflow Soldering Oven or Inline Nitrogen Vacuum Soldering Oven take inert gas protection a step further.

Vacuum Reflow Soldering Oven

A high-performance system combining vacuum environment and nitrogen to:

Eliminate voids in solder joints

Enable fluxless or low-residue soldering

Support applications like IGBT, MOSFET, and diode packaging

Inline Nitrogen Vacuum Soldering Oven

Ideal for mass production, it integrates nitrogen atmosphere and vacuum degassing for:

High yield and throughput

Consistent solder joint quality

Suitability for leadframe or ceramic substrates

These systems are particularly useful in power electronics, including diode and IGBT module assembly, where solder joint reliability is critical.

How Does Using Nitrogen Improve Quality and Reliability in Selective Wave Soldering?

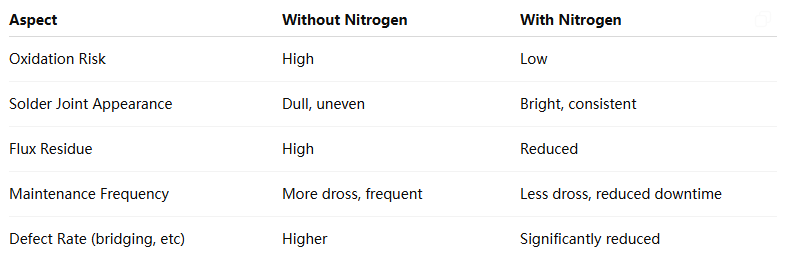

The addition of nitrogen in selective wave soldering provides measurable improvements:

Using nitrogen not only improves joint quality but also lowers operational costs in the long term by minimizing rework and material waste.

Are There Challenges in Using Nitrogen in Selective Soldering?

Yes, there are several considerations:

Cost of Nitrogen Supply: Especially in facilities without central gas delivery systems.

System Compatibility: Not all older soldering machines support nitrogen integration.

Process Balancing: Incorrect flow can cool the solder or displace flux.

However, these challenges are outweighed by the benefits in most medium-to-high volume applications, especially when working with sensitive or high-reliability components.

Can Nitrogen Use Be Optimized to Reduce Costs?

Absolutely. Manufacturers often take these measures:

Use On-site Nitrogen Generators: PSA systems to reduce bottled gas cost

Smart Gas Flow Control: Adjusting based on PCB complexity and dwell time

Zonal Application: Targeted delivery around solder nozzle instead of entire chamber

Scheduled Maintenance: Prevents leaks and ensures efficient gas use

What Industries Benefit Most from Nitrogen-Based Selective Soldering?

Sectors where reliability and clean joints are crucial gain the most:

Automotive Electronics (ECUs, sensors, BMS modules)

Power Semiconductors (e.g., IGBT, SiC devices)

Medical Devices (implantables, imaging PCBs)

Telecom and Networking Equipment

Aerospace and Military Hardware

These industries require consistent process quality, traceability, and low-defect rates—all supported by nitrogen-assisted selective wave soldering.

Conclusion: Why Nitrogen Is the Gas of Choice in Selective Wave Soldering

To prevent oxidation and achieve high-quality, reliable joints in selective wave soldering, nitrogen remains the go-to protective gas. Its inert properties, affordability, and compatibility with advanced soldering systems make it essential in both standard and high-precision applications.

Innovative solutions from companies like Chengliankaida Technology Co., LTD—featuring advanced platforms such as the Vacuum Reflow Soldering Oven and Inline Nitrogen Vacuum Soldering Oven—further elevate soldering reliability through controlled environments and intelligent process integration.

As the electronics industry moves toward miniaturization, high thermal performance, and void-free packaging, nitrogen will continue playing a central role in selective wave soldering and beyond.

Comments