Shot blasting machine is using in almost all industries that use metal. It is a necessary process for using steel grit and steel shot to remove surface stains, rust, and verify the product surface’s integrity. Compared to other surface treatment technologies, it is faster and more effective and preferred, because of its WPC (Metal surface cleaning ) treatment ability and environmental friendliness. Usually, this blasting method is also used for concrete.

Shot blasting machine

Shot blasting machine uses of centrifugal rotating turbine blades, throwing high-speed (about 70-90 m/s) steel media (steel, copper, aluminum or other materials of high-speed beads as blasting media), projected onto the surface at a certain angle. To achieve of deburr, de-sand, clean or strengthen the surface of the casting, or remove rust, paint or other coatings, etc.;

The shot blasting task determines the choice of abrasive media. In most cases is metallic materials.

Sandblasting machine

The Sandblasting media is pneumatically accelerated by compressed air (instead of a centrifugal turbine). The users can control the direction of the blast through a nozzle.

For special applications, an abrasive media-water mixture, is a wet blasting machine.

The sandblasting’s efficiency is decreases and costs increase. In most cases, consume of any type of dry or free-flowing abrasive media.

Function

Shot blasting mainly used to remove burrs, diaphragms and rust on the surface of steel products. Esperially in large quantities during the metal production process. It will affect the integrity and appearance of the object part. Which can roughness a surface profile that increases the adhesion of the coating, and achieve the purpose of strengthening the workpiece.

It is also possible to fully open the capillary pores on the surface of the concrete, allowing the sealant or binder to fully penetrate the concrete, exposing the concrete defects in advance.

Application areas and machinery

Surface cleaning

Shot blasting equipment is initially used in the foundry industry to remove sticky sand, oxide scale from the surface of steel and iron castings. This is also an indispensable preparation process before the quality inspection of the casting.

Workpiece strengthening

According to modern metal strength theory, increasing the dislocation stress inside the metal is the main direction to improve the strength of the metal.

- steel plate industry: The steel plate will have some burrs, which will affect the appearance of the steel, or the rust expose after the rain, can choose of the roller type steel plate pretreatment line.

- For beams, profiles: large size, high quality, high corrosion-resistant flat steel and large angle steel with unequal sides and thickness, use the roller type shot blast machine to ensure no longer have dead-angles.

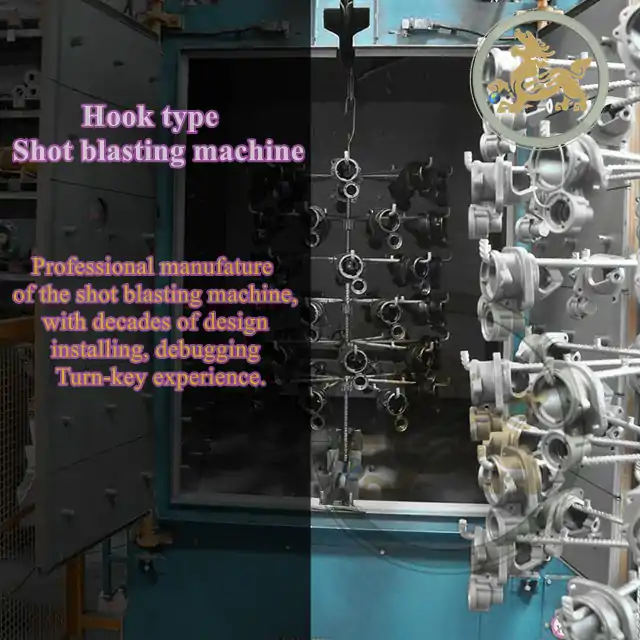

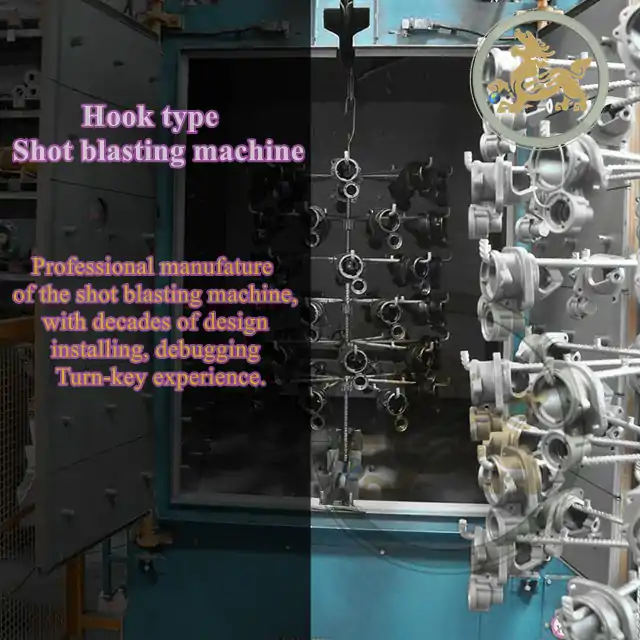

- hardware industry: In the hardware industry, there are a large number of parts and many types. Most parts need to clean, smooth, and flat on the surface. Generally, hook type or crawler shot blasting machines.

- Automobile industry: Many parts in the automotive industry need derust and polish. The shot blasting machine can achieve rust removal and polishing without affecting the shape and material strength. The shot blasting machine and sandblasting room is a welcome method.

- bearing and mold industry: The bearing and mold industry has high surface requirements to remove various burrs, impurities, etc.; recommend the rotary table shot blasting machine.

- valve factory: All kinds of valves are basically castings, suitable for crawler shot blast machine, which can clean 600-1000kg at one time.

- LPG gas tank: use the hook-through type and the special steel cylinder shot blasting machine, which has high efficiency and a good cleaning effect.

Shot media abrasive

- Stainless shot steel

- Chilled cast iron

- Casting shot ball

- Glass beads

- Ceramic balls

- Aluminum shot

- Mixed corundum

- Wire cut etc.

What is the difference between shot blasting machine and shot peening machine?

Shot blasting machine is primarily a surface finishing process. To modify the surface of parts to smooth rough surfaces, reshape surfaces, or remove surface contaminants. That is typically used to prepare the surface for subsequent operations (such as painting, coating, etc.) to improve adhesion and smoothness.

The biggest difference between shot peening machines is “peening”, which is improve the material properties of the surface to increasing the compressive stress.

www.shotblastech.com

Comments