Oxygen pressure swing adsorption (PSA) is a widely used technology for separating oxygen from air to produce high-purity oxygen gas. This process is efficient, cost-effective, and environmentally friendly, making it ideal for industries such as medical, chemical, and metallurgy. Unlike cryogenic distillation, which is energy-intensive, oxygen pressure swing adsorption leverages the selective adsorption properties of materials to isolate oxygen at ambient temperatures. This article outlines the key steps involved in the oxygen pressure swing adsorption process, providing a clear and objective understanding of its mechanics and applications.

What is Pressure Swing Adsorption?

Pressure swing adsorption is a gas separation technique that uses adsorbent materials, such as zeolites or activated carbon, to selectively capture specific gases from a mixture. In the context of oxygen pressure swing adsorption, the goal is to separate oxygen (O₂) from nitrogen (N₂) and other trace gases in atmospheric air. The process operates by cycling between high-pressure adsorption and low-pressure desorption phases, exploiting differences in the adsorption affinities of gases under varying pressures.

The oxygen pressure swing adsorption process is highly efficient because it can be performed in compact systems, making it suitable for both large-scale industrial applications and smaller, on-site oxygen generators. Companies like Hangzhou Z-Oxygen Intelligent Device Co., Ltd utilize this technology to provide tailored solutions for oxygen generation across various industries.

Key Steps in the Oxygen Pressure Swing Adsorption Process

The oxygen pressure swing adsorption process involves a series of well-defined steps that ensure the continuous production of high-purity oxygen. These steps are typically performed in two or more adsorption columns to maintain a steady output. Below, we break down the process into its core stages.

1. Air Compression and Pre-Treatment

The oxygen pressure swing adsorption process begins with the compression of ambient air. Atmospheric air, which contains approximately 21% oxygen, 78% nitrogen, and trace amounts of other gases (e.g., argon, carbon dioxide, and water vapor), is drawn into the system and compressed to a pressure typically between 4 and 10 bar. This compression increases the concentration of gas molecules, facilitating effective adsorption.

Before entering the adsorption columns, the compressed air undergoes pre-treatment to remove impurities that could damage the adsorbent material or reduce efficiency. This involves:

Filtration: Removing dust, oil, and particulate matter using compressed air filters.

Moisture Removal: Using dryers to eliminate water vapor, as moisture can degrade the performance of adsorbents like zeolites.

Carbon Dioxide Reduction: In some systems, additional filters reduce CO₂ levels to prevent competition with oxygen during adsorption.

Pre-treatment ensures that the air entering the oxygen pressure swing adsorption system is clean and dry, optimizing the performance of the adsorbent material.

2. Adsorption Phase

In the adsorption phase, the pre-treated, compressed air is directed into an adsorption column filled with a selective adsorbent, typically a zeolite molecular sieve. Zeolites are highly porous materials with a strong affinity for nitrogen due to their molecular structure. In oxygen pressure swing adsorption, the zeolite preferentially adsorbs nitrogen molecules while allowing oxygen and other non-adsorbed gases (e.g., argon) to pass through.

During this high-pressure phase, the following occurs:

Nitrogen molecules are trapped on the surface of the zeolite, reducing the nitrogen content in the gas stream.

Oxygen, which has a lower adsorption affinity, flows through the column and is collected as the product gas.

The output gas typically achieves an oxygen purity of 90–95%, suitable for most industrial and medical applications.

The adsorption phase continues until the zeolite becomes saturated with nitrogen, at which point the column can no longer effectively separate oxygen. To maintain continuous operation, the system switches to a second adsorption column while the first undergoes regeneration.

3. Depressurization and Desorption

Once the adsorbent in the first column is saturated, the oxygen pressure swing adsorption process transitions to the depressurization and desorption phase. The column is isolated from the compressed air feed, and the pressure is rapidly reduced, often to near-atmospheric levels. This pressure drop causes the adsorbed nitrogen to be released from the zeolite, a process known as desorption.

Depressurization is critical because it regenerates the adsorbent, preparing it for the next adsorption cycle. The released nitrogen, along with other trace gases, is vented to the atmosphere or, in some systems, collected for further use (e.g., in nitrogen PSA systems). The desorption phase ensures that the zeolite regains its capacity to adsorb nitrogen, making the oxygen pressure swing adsorption process cyclical and sustainable.

4. Purge and Pressure Equalization

To enhance efficiency, many oxygen pressure swing adsorption systems include a purge and pressure equalization step. During the purge phase, a small portion of the high-purity oxygen produced from the active column is redirected to the regenerating column. This oxygen flow helps "purge" residual nitrogen from the zeolite, ensuring thorough regeneration.

Pressure equalization is another optimization technique. Before fully depressurizing, the high-pressure gas from the saturated column is transferred to another column that is about to begin adsorption. This reduces energy losses and stabilizes the pressure across the system, improving the overall efficiency of the oxygen pressure swing adsorption process.

5. Cycle Repetition

The oxygen pressure swing adsorption process is cyclical, with each column alternating between adsorption and regeneration. In a typical two-column PSA system, while one column is adsorbing nitrogen and producing oxygen, the other is depressurizing and regenerating. The cycle time is carefully controlled, often lasting only a few minutes, to ensure continuous oxygen production.

Advanced oxygen pressure swing adsorption systems may use multiple columns or sophisticated control algorithms to optimize cycle timing and energy consumption. This ensures a steady supply of oxygen with minimal downtime or fluctuations in purity.

The oxygen pressure swing adsorption process offers several benefits, making it a preferred choice for oxygen generation:

Energy Efficiency: Compared to cryogenic distillation, PSA requires less energy, as it operates at ambient temperatures and moderate pressures.

Compact Design: PSA systems are compact and scalable, suitable for both large industrial plants and portable oxygen generators.

Cost-Effectiveness: The use of durable adsorbents like zeolites reduces maintenance costs, and on-site generation eliminates the need for oxygen transportation.

High Purity: Oxygen purity levels of 90–95% meet the requirements of most applications, including medical oxygen supply.

Applications of Oxygen Pressure Swing Adsorption

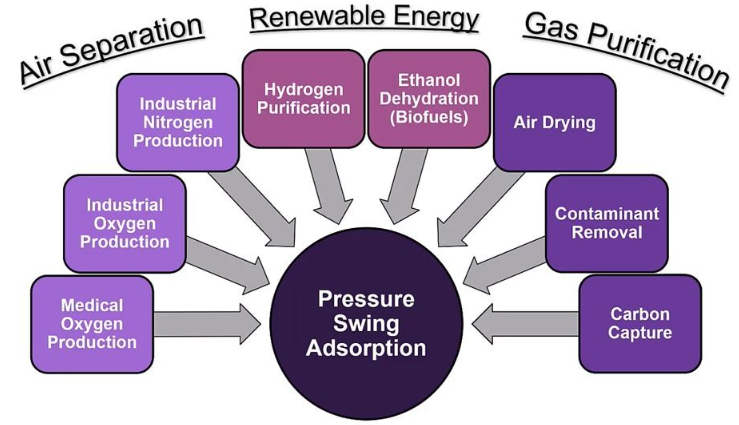

Oxygen pressure swing adsorption is employed across diverse industries due to its versatility and reliability. Key applications include:

Medical Oxygen Supply: PSA systems provide medical-grade oxygen for hospitals and clinics, especially in remote or resource-limited areas.

Industrial Processes: Oxygen is used in chemical manufacturing, metal cutting, and wastewater treatment.

Aerospace and Defense: PSA systems supply oxygen for high-altitude operations and emergency response.

Environmental Applications: Oxygen enhances combustion efficiency in incinerators and supports ozone generation for water purification.

Challenges and Considerations

While oxygen pressure swing adsorption is highly effective, it has some limitations. The process typically produces oxygen with a purity of up to 95%, which may not suffice for applications requiring ultra-high purity (e.g., semiconductor manufacturing). Additionally, the performance of PSA systems depends on the quality of the adsorbent and the precision of cycle control. Regular maintenance, such as replacing filters and monitoring adsorbent degradation, is essential to ensure consistent performance.

Conclusion

Oxygen pressure swing adsorption is a robust and efficient technology for producing high-purity oxygen from atmospheric air. By cycling through compression, adsorption, depressurization, and regeneration, PSA systems deliver a reliable oxygen supply for diverse applications. Its energy efficiency, compact design, and cost-effectiveness make it an attractive solution for industries worldwide. Understanding the steps of the oxygen pressure swing adsorption process highlights its technical elegance and practical value in meeting global oxygen demands.

Comments