Nylon syringe filters are essential tools in various fields, from laboratory research to industrial applications. These small yet powerful devices effectively filter particulates and other contaminants from liquids and gases, ensuring sample purity and preventing equipment damage. In this blog, we’ll dive into what nylon syringe filters are, their advantages, typical applications, and practical guidelines on how to use them. Key terms include nylon syringe filter, filter syringes, and how to use syringe filter.

What Are Nylon Syringe Filters?

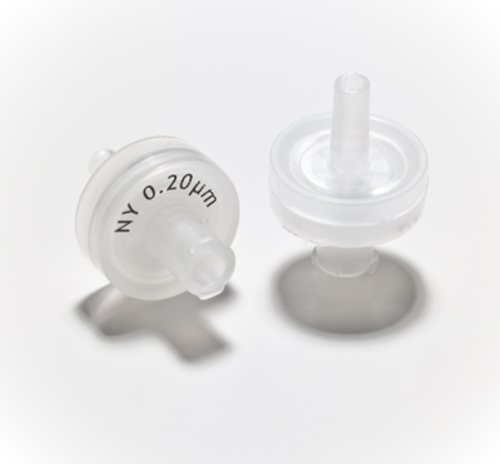

A syringe filter is a single use filter cartridge with a plastic housing that contains a filter membrane. It attaches to a syringe and is used to filter liquids or gases before they enter analytical or experimental equipment. Specifically, nylon syringe filters are made with nylon membranes, a synthetic polymer with excellent mechanical strength, chemical compatibility, and filtration capabilities.

Nylon syringe filters are popular due to their robustness, compatibility with many solvents, and ability to filter both aqueous and organic solutions. The filters are available in various pore sizes, making them adaptable to a wide range of filtration needs.

Advantages of Nylon Syringe Filters

High Chemical Compatibility: Nylon is compatible with a broad range of solvents, including most organic solvents and aqueous solutions. This versatility allows nylon syringe filters to be used in diverse applications, including chemical analysis, biological sample preparation, and industrial filtration.

Hydrophilic Nature: Nylon is inherently hydrophilic, meaning it easily interacts with water-based solutions, making it ideal for filtering aqueous solutions without the need for a pre wetting step. This property is especially valuable in laboratories where time and efficiency are key.

Superior Mechanical Strength: Nylon is a durable material that withstands high pressures without compromising filtration integrity. This robustness allows nylon syringe filters to handle more viscous samples or work in systems where higher filtration pressure is needed.

Low Extractables: Nylon syringe filters generally have low levels of extractables, which are undesirable substances that might leach from the filter and contaminate the sample. This characteristic is crucial in applications where purity is paramount, such as in analytical chemistry or biopharmaceutical processes.

Versatility in Pore Sizes: Available in various pore sizes, nylon syringe filters can accommodate a wide range of filtration needs, from removing large particles to ensuring the removal of very fine particulates. Typical pore sizes include 0.2 µm for fine filtration and 0.45 µm for general purpose filtration.

Common Applications of Nylon Syringe Filters

1. Laboratory Research and Sample PreparationNylon syringe filters are frequently used in laboratory settings for sample preparation, where researchers must remove particulates before analysis. They’re often used in High Performance Liquid Chromatography (HPLC) to filter samples and prevent column clogging. Their chemical compatibility with organic solvents makes them ideal for analytical applications in chemistry and biochemistry.

2. Pharmaceutical Industry

In the pharmaceutical industry, sterile filtration is critical. Nylon syringe filters help in filtering medications, vaccines, or biological samples, ensuring that the samples are free from particulate contaminants. They’re used to prepare sterile solutions for sensitive applications and to avoid introducing contaminants into sensitive processes.

3. Environmental Testing

Environmental testing often requires analyzing water, soil extracts, or atmospheric samples, all of which may contain various particles. Nylon syringe filters help in sample preparation by removing particulate matter, providing cleaner samples for accurate analysis.

4. Food and Beverage Testing

In quality control for the food and beverage industry, nylon syringe filters can filter aqueous and organic solutions used to analyze food samples. This step ensures that testing equipment remains uncontaminated and results are reliable, enhancing safety and quality control.

5. Industrial Applications

Nylon syringe filters are also utilized in industries like chemical manufacturing and electronics, where process fluids require particulate removal before being used in production or assembly lines. These filters ensure that process fluids remain free from unwanted particles, which can otherwise affect product quality or compromise machinery.

How To Use Syringe Filter?

Properly using a nylon syringe filter is critical for achieving optimal filtration efficiency and ensuring sample purity. Below are the key steps involved in using a syringe filter.

How To Select an Appropriate Filter?

Choose a nylon syringe filter with the right pore size for your application. A 0.45 µm filter is often sufficient for general filtration, while a 0.2 µm filter is more suitable for finer filtration needs.

Attach the Filter to the Syringe

Remove the protective cap from the syringe and attach the filter by twisting it onto the syringe’s Luer lock or slip fitting. Ensure a secure connection to prevent leaks during filtration.

Pre Rinse the Filter (Optional)

For critical applications, especially in cases where low extractables are essential, pre-rinsing the filter may help remove any remaining residues. Inject a small amount of solvent or buffer through the filter and discard this initial portion.

Filter the Sample

Draw your sample into the syringe, then press the syringe plunger gently to pass the sample through the nylon filter. Apply consistent pressure without excessive force, as too much pressure can damage the filter or cause leaks.

Dispose of the Filter After Use

Nylon syringe filters are typically single use devices. After filtration, safely dispose of the filter according to your laboratory’s waste disposal guidelines.

Why Choose Nylon Syringe Filters Over Other Materials?

While there are many types of syringe filters, nylon syringe filters offer unique advantages that make them a preferred choice for various applications:

Broad Solvent Compatibility: Unlike cellulose acetate or PVDF filters, nylon filters are more compatible with organic solvents, giving them a wider application range in analytical and industrial settings.

Strength and Durability: Nylon’s mechanical resilience allows for higher pressures, making it suitable for viscous samples and applications that require durable filtration.

Ease of Use in Aqueous Solutions: Nylon’s hydrophilicity simplifies the filtration process for water-based solutions, saving time and minimizing extra steps.

Important Tips for Using Nylon Syringe Filters

Avoid Using with Strong Acids or Bases

While nylon has excellent solvent compatibility, it’s less suitable for strong acids or bases, which can degrade the filter material. For such solutions, consider alternative materials like PTFE or PVDF.

Match Pore Size to Application Needs

Using the correct pore size is essential for effective filtration. Coarser filters may not remove finer particles, while finer filters may clog easily when filtering larger particles.

Apply Pressure Gradually

Applying pressure too quickly can compromise the filter’s structural integrity. Gradual, even pressure helps ensure effective filtration without damaging the filter.

Store Filters in a Clean, Dry Environment

Proper storage prevents contamination or physical damage before use, ensuring filters are in optimal condition when needed.

Nylon syringe filters play a vital role in ensuring sample purity and protecting laboratory and industrial equipment. Their combination of chemical compatibility, hydrophilicity, and mechanical strength makes them ideal for a range of applications, from environmental testing and pharmaceutical sample preparation to HPLC and industrial filtration. Their ease of use and availability in various pore sizes add to their versatility and appeal.

By understanding how to select and properly use a nylon syringe filter, researchers and industry professionals can enhance their filtration processes and ensure reliable, accurate results. For anyone looking to maintain clean, contaminant free samples without compromising on cost or quality, nylon syringe filters provide an efficient and effective solution.

Yongkang Medical is a leading manufacturer and supplier of high quality filter syringes. We specialize in designing and producing innovative products that meet the needs of our customers and exceed their expectations. Buy sterile syringe filter online, just contact us: czyk001@163.com or eric@yongkangcn.com

Comments