Pictures and posters are a popular and conventional means of embellishing any space, be it personal or professional. However, why settle for blending in when you can truly make a statement? Infuse vibrancy into your walls with distinctive designs that inject personality into your living or working environment. Discover the growing global appeal of laser cutting and how it has the transformative power to elevate any envisioned design into a captivating work of art.

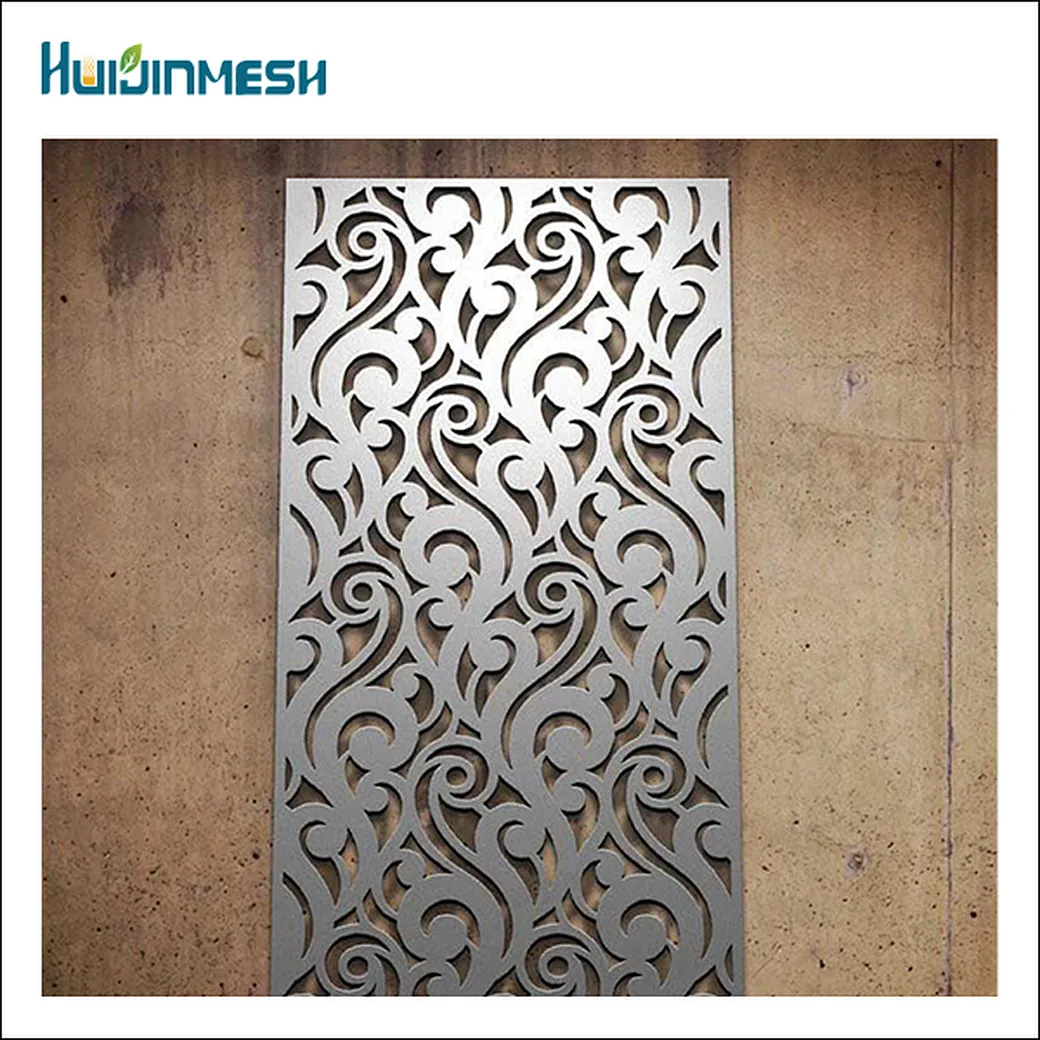

Laser-cut screens feature intricate patterns and designs etched into a chosen material. Our screens are crafted from a variety of materials including aluminum, stainless steel, mild steel, and corten steel. They serve versatile purposes and can be utilized in diverse settings such as luxury hotels, restaurants, offices, apartments, and homes. Tailored to suit any space, these screens seamlessly blend into their surroundings. Opting for laser-cut panels over conventional framed or unframed photographs offers numerous advantages. Virtually any design concept can be translated into a stunning masterpiece. Combining the robustness of steel with an elegant aesthetic, these panels are both lightweight and durable. Using metal as the medium ensures resilience against damage, even with frequent handling, promising longevity far beyond that of traditional photographs or pictures.

What Metals Can Be Laser-Cut?

A significant benefit of laser cutting lies in its versatility, capable of cutting through a wide array of materials ranging from thin metals to thicker ones, including wood and select types of plastic.

Laser cutting encounters minimal obstacles with most grades of:

- Mild steel / Low Carbon steel

- Cold rolled steel

- Stainless Steel

- Aluminum

- Titanium

- Brass

- Copper

With the introduction of CO2 laser cutting technology, the precision and swiftness typically associated with thinner materials can now be extended to thicker materials as well.

What Is the Process of Laser Cutting Sheet Metal?

Laser cutting of metal involves the utilization of laser beams to liquefy metals and alloys, resulting in precise, clean cuts. This process comprises two synchronized operations.

Initially, the material absorbs the concentrated laser beam, which provides the energy necessary for cutting. Subsequently, the cutting nozzle, aligned with the lasers, supplies the requisite process gas. This gas shields the processing head from vapors and splatters while aiding in the removal of excess material from the kerf.

Primarily, there are three techniques for laser cutting sheet metal:

1.Laser Beam Fusion Cutting

In laser beam fusion cutting, an inert gas, typically nitrogen, is used. This low-reactivity process gas continually vaporizes the material's cutting gap. By preventing oxidation at the cutting edge without impeding the process, inert gas facilitates the removal of molten material. This method is suitable for cutting flat, thin sheets of aluminum alloys and stainless steel, resulting in high aesthetic appeal and minimal finishing operations.

2.Laser Beam Sublimation Cutting

Laser beam sublimation cutting entails the immediate evaporation of material, transitioning directly from solid to gas (sublimation). Similar to fusion cutting, inert gases are employed to expel the material's vapor from the kerf, ensuring no oxidation occurs at the cutting edge. This method finds application in cutting organic materials like wood, leather, and textiles.

3.Laser Beam Flame Cutting

Laser beam flame cutting utilizes a combustible gas—oxygen—to expel molten material. The laser heats the workpiece, inducing spontaneous combustion post-melting. Oxygen gas enhances the cutting process through oxidation—an exothermic reaction. Ideal for cutting mild steel and fusible materials such as ceramics, this method may result in burns on the cutting surface due to the oxidizing nature of the gas. Proper adjustment of process parameters can mitigate the formation of burrs.

7 Benefits Of Sheet Metal Laser Cutting

Let's explore the advantages of using laser cutting for sheet metal in the manufacturing sector:

1.Precision and Accuracy

Laser cutting excels in precision, making it ideal for intricate cuts with tight tolerances. Machines are capable of achieving extreme precision, often up to 0.0005 inches. This accuracy is crucial for manufacturing processes requiring detailed specifications. Additionally, laser cutting produces minimal burrs, leaving behind clean, smooth edges.

2.Automated Process

Utilizing Computer Numerical Control (CNC) systems, laser cutting operates autonomously once programmed. This automation reduces the need for human intervention and labor while enhancing cutting efficiency.

3.Damage Prevention

Contrary to misconceptions, laser cutting minimally affects materials, preventing warping or distortion. The heat from lasers selectively targets specific areas, leaving surrounding material unaffected. Consequently, there's minimal risk of damage to the workpiece.

4.Compatibility with Various Materials

Laser cutting is versatile, capable of handling a wide range of materials including copper, aluminum, stainless steel, and titanium. Its ability to cut through various materials efficiently makes it a preferred choice for diverse manufacturing applications.

5.Cost-Effectiveness

Although laser cutting machines may have initial costs, they offer long-term cost savings. A single laser cutting machine can handle multiple cutting operations without the need for modifications. Moreover, the minimal maintenance requirements and reduced operational costs make it a cost-effective solution compared to traditional manufacturing tools.

6.Versatility

Laser cutting offers versatility, accommodating a wide range of cutting functions from simple to complex tasks. Its ability to handle intricate designs and tight tolerances makes it suitable for various industries and applications.

7.Low Energy Consumption

Despite requiring power for operation, laser cutters are energy-efficient compared to alternative cutting methods. The machines have fewer moving parts, resulting in lower energy requirements. Additionally, their high-speed cutting capability reduces energy consumption and saves time.

What Is the Best Place to Use Laser Cut Panels?

Are you an interior decorator seeking to offer your clients something distinctive, elegant, and of superior quality, yet affordable? Whether your clientele comprises families, small businesses, or larger establishments like hotels, restaurants, or companies, our laser-cut panels are tailored to suit each of their needs. By blending their preferred colors, patterns, and materials, and incorporating backlighting, you can transform their space into an inviting area that they, along with their friends or customers, will relish spending time in.

1.Residential and Commercial Spaces

Elevate the decor of your home or office beyond traditional wall hangings such as photographs or paintings. Huijin Metal provides an avenue for creative expression with a myriad of panel design options. Imagine bringing the essence of a forest or the majesty of a sea wave into your room. By mixing and matching colors, patterns, and materials, you can curate your own masterpiece. Backlighting adds another dimension, allowing you to set the ambiance according to your preferences, whether it's a romantic setting or a lively atmosphere for celebrations. Additionally, installing backlighting can help conserve energy and save on utility costs, while transforming any space into a captivating environment.

2.Hospitality and Retail Environments

In customer-centric settings like hotels, restaurants, and shops, laser-cut panels serve a dual purpose beyond mere decoration. They can convey a message or narrate the story of your business through customized displays of logos, slogans, or mission statements. These panels not only enhance aesthetics but also serve as durable promotional tools that can withstand the rigors of daily use. Our signage products, including those with background lighting, are particularly popular for interior and exterior applications in various commercial settings. They can be customized to meet your specific branding and promotional needs, ensuring a lasting impression on your clientele.

3.Outdoor Spaces

Our panels and walls are not confined to indoor use but are also suitable for outdoor applications in gardens or on balconies. Crafted from weather-resistant materials, they are designed to withstand outdoor elements, ensuring longevity and durability. Before selecting a decorative wall for outdoor use, consult with us to receive professional advice on the best materials for your specific requirements and how to properly maintain them for optimal longevity.

We can help you choose the perfect solution for your space by contacting inquiry@huijinwiremesh.com.

Comments