Reverse Engineering Process

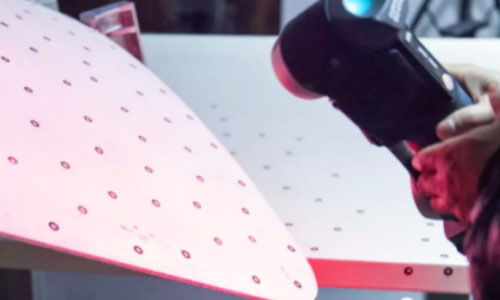

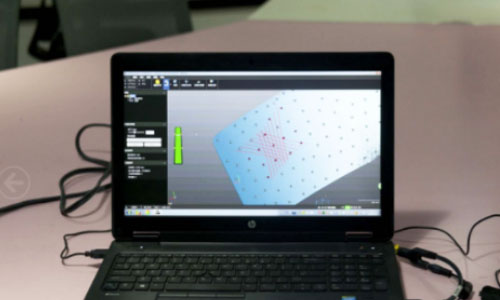

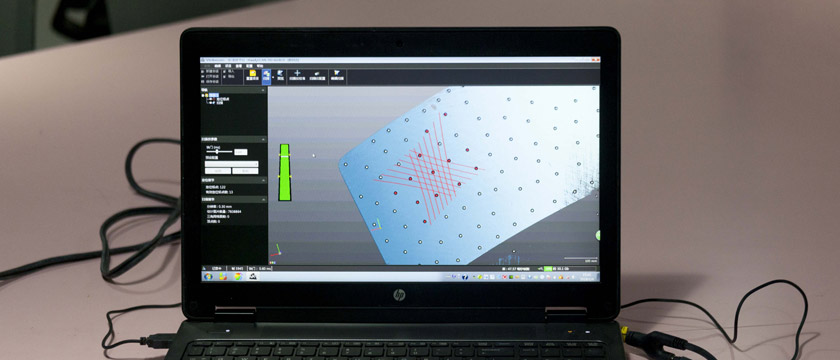

1. To obtain 3D date by 3D scanning for objects.

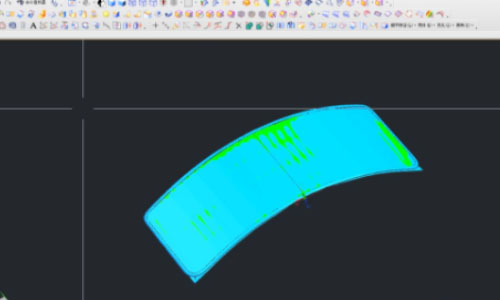

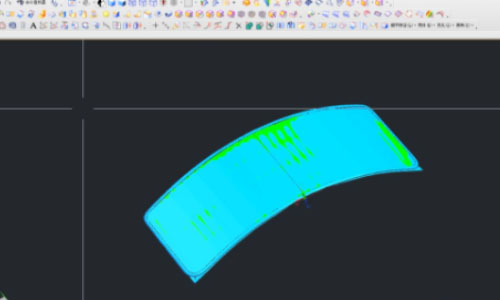

2. By generating point clouds, extracting features, and using reverse engineering software to have date processing for the point clouds.

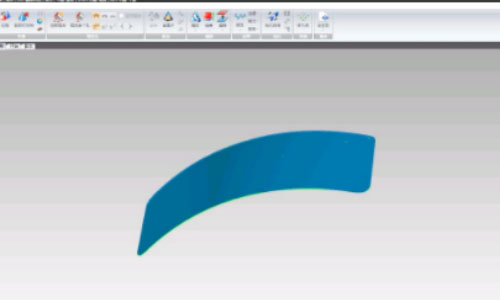

3. Reverse modeling.

4. Compare evaluation: To inspect the geometric error and make necessary modifications by using a variety of 3D engineering software.

Advantages of Reverse Engineering

- To shorten the product design and development cycle, speed up the replacement speed of the products

- To reduce the cost and risk of developing new products;

- To speed up the geometric and Serialization Design for the products;

- It is suitable for both single piece and small batch production, especially benefit for making molds.

Reverse Engineering Applicaitons

- automotive manufacturing

- aerospace

- electronics

- medical field

- cultural relics

- sculpture

- construction

- scientific research

Why Choose Us for Reverse Engineering Service?

We have professional reverse engineers and advanced 3D laser scanners, which can quickly and easily obtain 3D data of scanned objects. Through professional 3D post software, we

biggest printer can accurately obtain various structures from curved threads to ribs and cavities. You can also convert 3D drawings into traditional and commonly used 2D engineering drawings through the corresponding software according to your own needs. You only need to provide us with a physical model, we can also come to the on-site service, let you experience professional services.

With more than 20 years of 3d scanning reverse engineering service and 3D copying experience, we have successfully provided professional reverse engineering services for customers in reverse engineering projects of automotive manufacturing, aerospace, mold manufacturing, electronics, consumer, medical, cultural relics, sculpture, construction, scientific research and other industries. The solution helps industry customers shorten the development cycle, increase production efficiency and improve product quality.

If you are looking for a professional and reliable service provider for 3d reverse engineering, please contact our professional team at

info@duchgroup.com or contact us using the inquiry form on this website, we will provide quotes and suggestions free of charge.

Comments