The increasing functionality of smartphones and other devices necessitates smaller components capable of supporting high density mounting.

Silicon capacitors utilizing thin film semiconductor technology offer greater capacitance within a more compact form factor compared to conventional multilayer ceramic capacitors (MLCCs). Simultaneously, their ability to maintain stable temperature characteristics and exhibit excellent reliability is fueling their widespread adoption across various applications.

Introduction of Silicon Capacitors

Capacitors play a crucial role in electronic circuits, serving a wide range of applications such as storing electric charge, delaying voltage changes, creating resonant circuits, and filtering out unwanted signals. The choice of dielectric material is a pivotal factor that determines the capacitor's characteristics and applications. Other influential factors include packaging and the structure of the plates. Common dielectric materials encompass aluminum and tantalum oxide, ceramic, plastic film, polymer, glass, mica, and paper.

Aluminum or tantalum plate capacitors, featuring oxide dielectric materials, find extensive use in applications requiring high capacitance. These electrolytic capacitors, while providing high capacitance, exhibit drawbacks such as instability, poor tolerances, and performance degradation under conditions of high leakage current or elevated temperatures. Plastic film and paper capacitors are preferred for circuits demanding reliable aging performance, stability, and substantial current carrying capability. Ceramic capacitors are suitable for high frequency applications, although they may show deficiencies in aging performance. Mica and glass capacitors, offering extremely high stability, reliability, and tolerance to high voltages and temperatures, are reserved for specific applications due to their relatively higher cost and are not commonly used in budget friendly devices.

In the realm of high density capacitors, those with silicon based dielectrics like silicon dioxide and silicon nitride excel. Capacitors featuring silicon dielectrics prove ideal for applications requiring exceptional stability, reliability, and resilience to high temperatures. These capacitors, known for their performance characteristics, are particularly well suited for deployment in demanding environments. The following delineates the key strengths and limitations of capacitors with silicon based dielectrics.

The

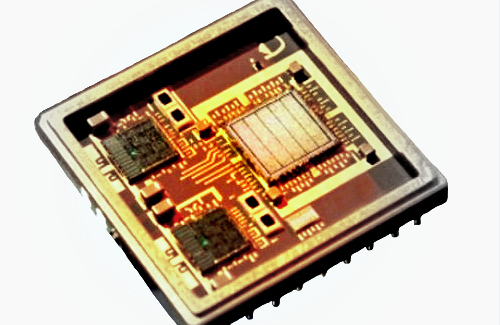

capacitor silicon adopts a trench structure to enhance capacitance per unit area on the substrate. Leveraging miniaturization technology enables precision processing in 1 µm increments, eliminating chipping during external formation and refining dimensional tolerances to within ±10 µm.

Strengths of Silicon Based Dielectrics

High Stability at High Temperature

The performance of the majority of capacitors is notably influenced by exposure to high temperatures.

Silicon capacitors, available in various temperature ratings, typically extend up to 250°C. High temperature silicon capacitors prove well suited for a diverse array of demanding applications, including aircraft engine controls, avionics systems, automotive systems, downhole oil exploration systems, and military applications. Notably, silicon capacitors exhibit highly stable capacitance performance concerning both voltage and temperature. While there is a limitation on the maximum capacitance of silicon capacitors, they do not undergo capacitance aging. Furthermore, in contrast to X7R and X8R capacitors, the reliability and capacitance of silicon capacitors remain uncompromised even under DC bias conditions.

High Potential for Miniaturisation

Silicon based dielectrics are commonly employed in the production of high density electronic devices. High density silicon capacitors are typically crafted in ultra deep trenches, showcasing minimal leakage current and a low loss factor. Passive Integration Connective Substrate (PICS) stands out as the prevailing technology for implementing high density capacitors. This technique facilitates the realization of Multi Chip Modules (MCMs) and Chip on Board (COB), contributing to the creation of smaller components with low power consumption. Moreover, PICS enables the integration of multiple fundamental functions into a singular product, thereby aiding in cost reduction during manufacturing. With the incorporation of cutting edge technologies, considerable advancements in volumetric efficiency have been attained. Anticipated growth in demand for high performance and miniaturized components suggests a continued improvement in the volumetric efficiency of silicon capacitors. Remarkably, silicon capacitors with layers thinner than those achieved through Multilayer Ceramic Capacitor (MLCC) technology have already been successfully developed.

Leakage Current Stability at High Temperature

Leakage current, a crucial capacitor parameter, undergoes changes when a capacitor is exposed to elevated temperatures. The dielectric material plays a pivotal role in determining the leakage current of a capacitor. Excessive stress on the dielectric material can substantially elevate the leakage current. The charging voltage and dielectric thickness also exert a minor influence on the capacitor's leakage current. In contrast to numerous high temperature capacitors available in the market, silicon capacitors exhibit noteworthy characteristics in terms of leakage current and temperature. Furthermore, silicon based dielectrics boast impressive insulation resistance, rendering them an unparalleled choice for coupling, blocking, and timing circuits.

Low Failure Rate

Capacitors play a diverse role in electronic circuits, establishing themselves as one of the most prevalent passive components within electronic systems. The reliability of a capacitor is contingent upon its failure rate, and capacitors, in comparison to other passive components, tend to exhibit a relatively higher failure rate. Factors such as operating time and loading conditions play pivotal roles in determining the failure rate of a capacitor. Through comparative reliability tests, it has been demonstrated that high temperature silicon capacitors boast superior FIT (Failure In Time) rates when contrasted with high temperature X8R capacitors.

Limitations of Silicon Based Dielectrics

Limited Maximum Capacitance

While silicon capacitors demonstrate remarkable attributes such as elevated stability at high temperatures, minimal leakage current, high insulation resistance, and dense capacitance, there exists a limitation on the maximum attainable capacitance. Anticipated progress in technology is poised to address this technological constraint. Manufacturers, in addition to refining the fabrication process, are actively investigating alternative dielectrics as potential solutions to overcome the primary technical hurdles associated with silicon based dielectrics.

Charge Leakage

SiO2 is a commonly employed material in the manufacturing of capacitors for microelectronic devices. These capacitors are created by oxidizing silicon and utilizing the resulting oxide as the dielectric material. Because capacitance is directly linked to the area of the dielectric material and inversely proportional to its thickness, manufacturers in the electronic device industry have been reducing both the area and thickness of the dielectric material to achieve miniaturized and high density devices. As the thickness of the SiO2 dielectric film decreases, there is an increase in charge leakage through the dielectric material. Beyond a certain threshold, the capacitor encounters challenges in effectively storing charge due to the heightened leakage problem. Although DRAM manufacturers are adopting deep trenches to mitigate leakage issues, the limitation imposed by dielectric thickness remains a significant obstacle to the miniaturization of microelectronic devices. In addition to refining the implementation process, manufacturers are actively exploring alternative dielectrics as a strategy to overcome this limitation.

KUKE will continue to strive to meet customer needs as electronic components that can contribute to new generation power supplies, such as high quality silicon capacitors. If you have any question about sio2 capacitance, please contact

KUKE immediately.

Comments