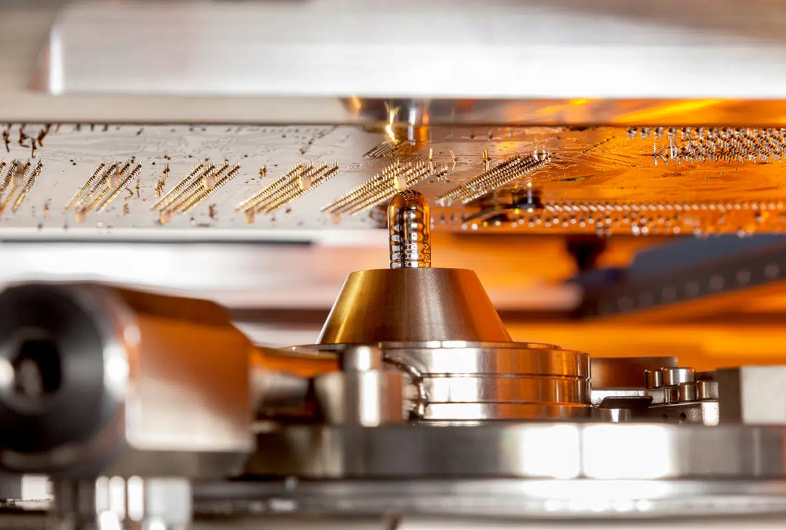

A selective soldering machine is designed to solder specific through-hole components without affecting nearby surface-mounted parts. Unlike traditional wave soldering, selective soldering targets only predefined areas, offering higher precision and reduced thermal stress.

For manufacturers serving high-reliability markets, the selective soldering machine has become a key solution for complex PCB assemblies where accuracy and repeatability are critical.

Why Has Selective Soldering Replaced Traditional Wave Soldering in Many Applications?

Traditional wave soldering exposes the entire PCB to molten solder, increasing the risk of thermal damage and unwanted solder bridges. As board density increases, this method becomes less suitable.

A selective soldering machine allows localized soldering, minimizing heat exposure and reducing defects. This targeted approach aligns better with modern PCB designs that combine mixed technologies and tight component spacing.

How Does a Selective Soldering Machine Improve Soldering Precision?

Precision is achieved through controlled nozzle movement, programmable solder paths, and accurate positioning systems. These features ensure solder is applied only where needed.

By using a selective soldering machine, manufacturers can achieve consistent solder joints even on complex layouts, reducing variability caused by manual intervention or full-board soldering methods.

What Are Common Process Challenges in Selective Soldering?

Despite its advantages, selective soldering still faces challenges such as improper solder flow, flux misapplication, and thermal imbalance. Incorrect parameter settings can lead to defects similar to those seen in other soldering processes.

A well-configured selective soldering machine requires careful optimization of temperature profiles, solder height, and dwell time to maintain stable results across production runs.

How Does Temperature Profiling Affect Selective Soldering Quality?

Temperature profiling determines how heat is transferred to pads, leads, and solder. Insufficient heating leads to cold joints, while excessive heating risks component damage.

In a selective soldering machine, precise thermal control ensures solder wets properly and solidifies with the desired microstructure. Stable profiles are essential for achieving consistent joint strength and appearance.

Why Is Flux Control Critical in Selective Soldering Processes?

Flux prepares metal surfaces by removing oxides and promoting solder wetting. However, uneven or excessive flux application can cause residues, contamination, or poor joint formation.

A selective soldering machine must synchronize flux delivery with heating and soldering stages. Proper flux control improves wetting efficiency and reduces post-solder cleaning requirements.

How Does PCB Design Influence Selective Soldering Results?

PCB layout decisions such as pad size, hole diameter, and component spacing directly affect soldering outcomes. Poor design can limit solder access or create uneven heat distribution.

Designs optimized for selective soldering machine processes help ensure smooth solder flow and reduce the likelihood of defects such as insufficient fill or bridging.

Why Is Void Formation Still a Concern in Selective Soldering?

Voids are trapped gases within solder joints that reduce thermal conductivity and mechanical reliability. In power electronics, voids can cause localized overheating and early failure.

To address this issue, some manufacturers integrate vacuum-assisted solutions such as the Vacuum Reflow Oven to complement selective soldering, especially in high-reliability assemblies.

How Can Advanced Atmosphere Control Improve Selective Soldering?

Oxidation negatively affects solder wetting and joint consistency. Controlling the soldering atmosphere helps reduce oxide formation during the process.

Equipment such as the Inline

Void-free Reflow Oven for Diode is often used in combination with selective soldering to improve joint integrity in sensitive electronic components.

Why Is Process Monitoring Essential for Selective Soldering Stability?

Without proper monitoring, small deviations in temperature, solder level, or nozzle alignment can quickly lead to defects. These issues may not be immediately visible but can impact long-term reliability.

Integrating sensors and feedback systems into a selective soldering machine allows real-time adjustments and ensures consistent quality throughout production.

How Does Automation Reduce Human Error in Selective Soldering?

Manual soldering depends heavily on operator skill and consistency. Automation reduces variability by following predefined programs and repeatable movements.

A selective soldering machine ensures each joint is produced under the same conditions, improving yield and reducing dependence on manual expertise.

Why Is Operator Knowledge Still Important with Automated Equipment?

Although selective soldering is automated, skilled operators are still essential. Incorrect setup, poor maintenance, or misunderstanding of process behavior can compromise results.

Well-trained personnel can optimize selective soldering machine parameters and respond effectively to changes in materials or design requirements.

How Does Selective Soldering Support High-Reliability Applications?

Industries such as power electronics, automotive, and industrial control demand consistent solder joint quality. Failures in these sectors can lead to costly downtime or safety risks.

Research and process development efforts, including those involving Chengliankaida Technology.co.,LTD, have helped refine selective soldering techniques to meet these demanding reliability standards.

Why Is Continuous Optimization Necessary for Selective Soldering Processes?

As electronic designs evolve, soldering requirements change. New materials, tighter tolerances, and higher power densities require ongoing process refinement.

Regular optimization of selective soldering machine parameters ensures manufacturers remain competitive and capable of meeting future production challenges.

What Should Manufacturers Focus on When Implementing a Selective Soldering Machine?

Successful implementation requires attention to equipment capability, process control, PCB design, and operator training. A holistic approach minimizes defects and maximizes consistency.

By understanding how a selective soldering machine operates and what influences its performance, manufacturers can achieve reliable solder joints and stable production outcomes, supported by shared industry experience from organizations such as Chengliankaida Technology.co.,LTD.

Comments