The air separation unit market plays a pivotal role in meeting the global demand for industrial gases such as oxygen, nitrogen, and argon. These gases are essential across industries like healthcare, metallurgy, chemicals, and energy, making air separation units (ASUs) indispensable. As of March 2025, the air separation unit market continues to expand, driven by industrial growth, technological advancements, and increasing sustainability efforts. This article delves into the market’s size, key trends, and factors influencing its trajectory, offering insights into this dynamic industry without a sales pitch—just the facts.

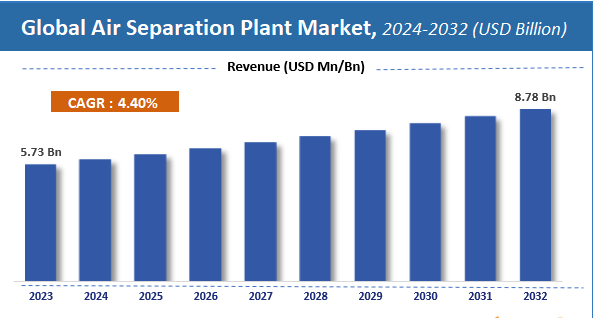

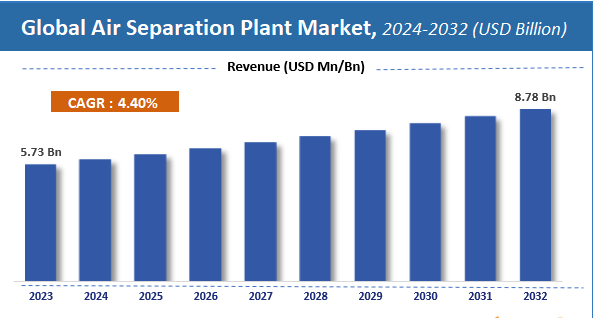

The air separation unit market size reflects the economic value of equipment and systems designed to separate atmospheric air into its primary components. Recent industry reports provide a range of estimates, but a consensus suggests the global market was valued between USD 5.4 billion and USD 5.9 billion in 2023. Projections indicate growth to USD 6.8 billion to USD 8.8 billion by 2030–2033, with compound annual growth rates (CAGRs) ranging from 4.3% to 5.5%. These figures highlight the air separation unit market’s steady expansion, fueled by diverse applications and regional industrialization.

The variation in estimates stems from differences in scope—some reports focus solely on cryogenic systems, while others include non-cryogenic technologies like pressure swing adsorption (PSA) and membrane separation. For a company like Hangzhou Z-Oxygen, which offers both cryogenic air separation series and PSA oxygen/nitrogen generators, this broad market definition is particularly relevant, as it encompasses their entire product portfolio.

Key Drivers of the Air Separation Unit Market Growth

What propels the air separation unit market forward? Several interconnected factors contribute to its growth, aligning with global industrial and environmental trends.

Industrial Demand for Oxygen and Nitrogen

Oxygen and nitrogen dominate the air separation unit market due to their widespread use. The steel industry, for instance, relies heavily on oxygen for blast furnace operations, with global steel production reaching 1,715.1 million tons in 2023. Nitrogen, meanwhile, is critical in chemical manufacturing, electronics, and food processing for applications like inerting and cryogenic freezing. The air separation unit market thrives on this demand, as industries require reliable, high-purity gas supplies—needs met by technologies like cryogenic plants and PSA generators.

Healthcare Sector Expansion

The healthcare industry has emerged as a significant driver for the air separation unit market, particularly for oxygen production. Medical-grade oxygen, produced by ASUs, supports respiratory therapies, surgical procedures, and emergency care. The COVID-19 pandemic underscored this need, prompting investments in oxygen generation systems, especially in developing regions. For example, the Global Alliance for Oxygen estimates a USD 4 billion investment by 2030 to boost oxygen access in low- and middle-income countries, directly impacting the air separation unit market.

Energy and Sustainability Trends

The push for cleaner energy sources, such as hydrogen production, also influences the air separation unit market. ASUs provide oxygen for gasification processes and nitrogen for hydrogen-related applications like steam methane reforming. As governments and industries prioritize decarbonization, energy-efficient ASUs—such as those with renewable power integration—are gaining traction, expanding the market’s scope.

The air separation unit market is defined by its technological diversity, with each method catering to specific industrial needs. Companies like Hangzhou Z-Oxygen leverage these technologies to address varied demands, from large-scale cryogenic plants to compact PSA systems.

Cryogenic Air Separation Units

Cryogenic distillation remains the backbone of the air separation unit market, especially for high-volume, high-purity gas production. This process cools air to extremely low temperatures, separating it into liquid oxygen, nitrogen, and argon via fractional distillation. It’s ideal for large-scale applications, such as steel mills or chemical plants, and aligns with products like Z-Oxygen’s cryogenic air separation series deployed in Russia. The air separation unit market benefits from cryogenic systems’ ability to co-produce liquid gases, meeting demands for low-temperature storage solutions.

Pressure Swing Adsorption (PSA) Systems

Non-cryogenic technologies, particularly PSA, are carving a growing niche in the air separation unit market. PSA systems use adsorbent materials to selectively capture gases, offering a cost-effective, energy-efficient alternative for smaller-scale oxygen or nitrogen generation. This technology suits applications like Z-Oxygen’s PSA nitrogen generators in Thailand or container oxygen generators in Chile, where portability and simplicity are key. The air separation unit market sees PSA’s rise due to its flexibility and lower operational costs, appealing to industries with moderate gas needs.

Emerging Innovations

Advancements in membrane separation and intelligent control valves—areas where Z-Oxygen also excels—are further shaping the air separation unit market. These innovations enhance efficiency, reduce energy consumption, and enable customization of gas purity levels, aligning with sustainability goals and

broadening market appeal.

Geographic trends reveal where the air separation unit market is gaining momentum, driven by regional industrialization and infrastructure development.

Asia-Pacific: The Market Leader

Asia-Pacific dominates the air separation unit market, accounting for the largest share and the fastest growth. Rapid industrialization in China, India, and Southeast Asia fuels demand for industrial gases, supported by steel production, electronics manufacturing, and healthcare investments. China alone produces over half of the world’s steel, relying heavily on ASUs. Projects like Z-Oxygen’s PSA nitrogen generators in Thailand exemplify this region’s appetite for air separation solutions, making it a hotspot for market expansion.

North America and Europe: Focus on Innovation

In North America and Europe, the air separation unit market emphasizes technological upgrades and sustainability. The U.S., a net exporter of crude oil, uses ASUs for enhanced oil recovery, while Europe invests in energy-efficient systems to meet strict environmental regulations. These regions prioritize advanced ASUs, such as those with digital controls or carbon capture integration, reflecting a mature but evolving market.

Emerging Markets: Untapped Potential

Countries like Turkey, South Africa, and Chile—where Z-Oxygen has deployed liquid oxygen storage tanks, oil-free compressors, and container oxygen generators—represent emerging opportunities in the air separation unit market. Industrial growth and healthcare needs in these regions drive demand for both large-scale and modular ASU solutions.

What Challenges and Opportunities Lie Ahead for the Air Separation Unit Market?

The air separation unit market faces a mix of hurdles and prospects as it evolves.

Challenges: Costs and Energy Use

High initial investment costs and energy-intensive operations pose challenges for the air separation unit market. Cryogenic systems, while efficient for large-scale production, require significant capital and power, potentially limiting adoption in cost-sensitive regions. PSA systems mitigate this but may not scale as effectively for massive industrial needs.

Opportunities: Sustainability and Customization

On the flip side, the air separation unit market is ripe with opportunities. The shift toward energy-efficient ASUs, renewable energy integration, and tailored gas purity solutions aligns with global sustainability goals. Companies innovating in these areas—like Z-Oxygen with its intelligent control valves—can tap into growing demand across diverse industries.

Future Outlook

Looking ahead to 2030 and beyond, the air separation unit market is poised for robust growth. Analysts predict a market size approaching USD 10 billion by 2034, driven by industrialization, healthcare advancements, and clean energy initiatives. The versatility of ASU technologies ensures their relevance, whether for large cryogenic plants or portable PSA units.

Conclusion

The air separation unit market is a dynamic and expanding sector, with its size reflecting the critical role of industrial gases in modern life. From oxygen in hospitals to nitrogen in factories, ASUs meet diverse needs through technologies like cryogenic distillation and PSA. As of March 2025, the market’s growth trajectory—spanning Asia-Pacific’s industrial boom to North America’s innovation focus—underscores its global significance. Challenges like energy costs exist, but opportunities in sustainability and customization promise a bright future for the air separation unit market.

Comments