Custom Electronics specializes in providing

mica capacitors and subcomponents designed for high voltage and high temperature applications in the aerospace industry, particularly for space and satellite applications.

Since its establishment in 1964, CEI has been at the forefront of designing and manufacturing top quality custom reconstituted mica paper capacitor. With a portfolio boasting over 15,000 unique designs, CEI's capacitors find applications in a multitude of demanding scenarios. Throughout its history, each high voltage mica capacitor has been meticulously tailored to meet the specific needs of individual customers.

These capacitors serve various critical applications, including power supplies for communication and weather satellites, pulsed power systems, radar transmitters, guidance and surface radar systems, high voltage transmitters, High Voltage Traveling Wave Tube (TWT) power supplies, ignition systems, laser devices, and transmitter power supplies for electronic countermeasures (ECM).

CEI utilizes "Grade A" mica paper in its capacitors due to its exceptional dielectric properties. Mica paper, composed of flexible, continuous, and uniform layers of reconstituted mica, serves as excellent electrical insulating material with a paper like structure, formed by small, thin overlapping platelets.

The mica paper employed by CEI undergoes rigorous quality checks, ensuring the production of high voltage reconstituted mica paper capacitors. These capacitors are trusted by leading high tech companies for applications in space age radar, missiles, satellites, ignition systems, detonation systems, cryogenic systems, transmissions, lasers, medical equipment, and oil and gas exploration.

Beyond mica capacitors, CEI extends its offerings to a range of electronic assemblies and modules. These modules typically include capacitors, resistors, diodes, coils, spark gaps, and voltage dividers, encapsulated with CEI's unique epoxies in molds or housings.

Designed for high altitude applications and diverse environments, modules feature terminations like wire leads, threaded studs, turret terminals, high voltage connectors, and cable assemblies. The operational temperature of modules varies based on internal components, epoxy selection, and the intended use.

CEI's products bring numerous advantages to the space and satellite industry, including radiation resistance, high temperature operation, corona resistance, capacitance stability concerning temperature, voltage, frequency, and mechanical stresses, shock and vibrational resistance, as well as fractional voltage or charge loss.

The company's engineering team stays abreast of the latest technological developments in materials, processes, and packaging, ensuring optimal designs. Collaborating closely with customers' mechanical and electrical design teams, CEI delivers customized capacitor designs with minimal response time.

What are Mica Capacitors?

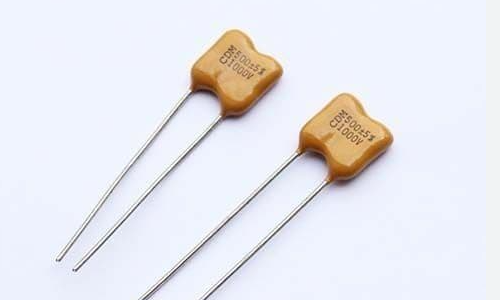

Mica, a group of natural minerals, serves as the dielectric in silver

mica capacitors. There are two main types of mica capacitors: clamped mica capacitors, now considered obsolete due to their inferior characteristics, and silver mica capacitors, which have replaced them. Silver mica capacitors are constructed by layering mica sheets coated with metal on both sides, and the assembly is encased in epoxy for environmental protection.

Silver mica capacitors are preferred in designs requiring stable and reliable capacitors of relatively small values. These capacitors exhibit low loss characteristics, enabling their usage at high frequencies, and their values remain relatively constant over time.

Mica minerals demonstrate excellent electrical, chemical, and mechanical stability, attributed to their specific crystalline structure. This structure allows the production of thin sheets ranging from 0.025 to 0.125 mm. Muscovite and phlogopite mica are the most commonly used varieties, with muscovite offering superior electrical properties and phlogopite having higher temperature resistance. Mica is sourced from regions such as India, Central Africa, and South America. The variability in raw material composition results in higher costs for inspection and sorting.

Notably, mica does not react with most acids, water, oil, and solvents, further contributing to its suitability for capacitor applications.

Characteristics of Mica Capacitors

Precision and tolerances

Silver mica capacitors exhibit an impressive minimum tolerance for capacitor values, which can be as low as ±1%. This level of tolerance surpasses the precision offered by practically all other types of capacitors. In contrast, specific ceramic capacitors may have tolerances reaching up to ±20%.

Stability

Mica capacitors demonstrate exceptional stability and accuracy, with minimal changes in capacitance over time. This stability is attributed to the absence of air gaps in their design, eliminating factors that could alter their performance. Additionally, the assembly is shielded from moisture and other environmental effects through the use of epoxy resin. As a result, external factors such as air humidity have negligible impact on mica capacitors.

Not only does the capacitance remain stable over time, but it also exhibits consistency across a broad range of temperature, voltage, and frequency. The average temperature coefficient hovers around 50 ppm/°C, further emphasizing their reliability under varying operating conditions.

Low losses

Mica capacitors are distinguished by their low resistive and inductive losses, denoting a high Q factor. Their attributes are predominantly frequency independent, making them suitable for applications at high frequencies. However, these exceptional characteristics come with a trade off – silver mica capacitors are relatively bulky and come at a higher cost.

Applications for Mica Capacitors

Silver

mica capacitors find utility in applications requiring low capacitance values, high stability, and minimal losses, making them particularly suitable for power RF circuits where stability is paramount.

These capacitors are commonly employed in high frequency tuned circuits like filters and oscillators. Additionally, they serve in pulsed applications as snubbers. While silver mica capacitors were once highly popular for their quality, they are gradually being replaced in contemporary applications due to their relatively larger size and higher cost, which can reach several USD per unit.

In low power RF applications, ceramic capacitors emerge as a viable alternative to mica capacitors. For scenarios where capacitance tolerances and low losses are crucial, Class 1 ceramic capacitors provide a cost effective solution with similar tolerances.

Despite the shift to alternative capacitor types, silver mica capacitors remain indispensable in certain applications. Circuit designers, particularly in high power applications like RF transmitters, still prefer mica capacitors. Moreover, high voltage applications continue to rely on silver mica capacitors, benefitting from mica's high breakdown voltage.

The construction of silver mica capacitors is relatively straightforward. In the past, clamped mica capacitors utilized thin sheets of mica layered with thin sheets of silver, which were then clamped together, and electrodes were added. However, the physical imperfections in both mica and silver layers resulted in small air gaps, restricting the precision of clamped mica capacitors. These air gaps could introduce issues related to mechanical stresses, leading to changes in capacitance values over time.

KUKE insists on supplying only original electronic components, such as high quality mica capacitors. If you have any question, please contact

KUKE immediately.

Comments