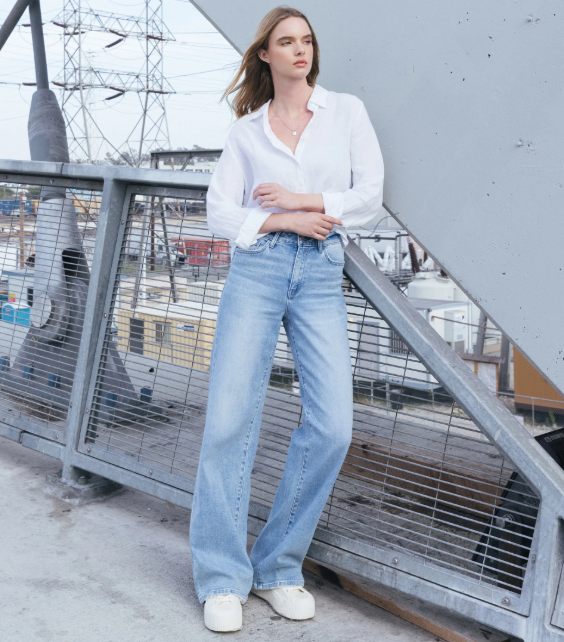

Thin legs are often associated with elegance and lightness, but many people feel unsure about how to wear shorts without appearing overly narrow or unbalanced. The key lies not in hiding slim legs, but in choosing the best shorts for thin legs that enhance proportion, structure, and visual harmony.

Professional designers and apparel engineers agree that leg appearance is influenced by cut, fabric behavior, color contrast, and silhouette. When these elements are well-balanced, shorts can visually add dimension, improve proportions, and create a confident overall look.

Why Does Fit Matter When Choosing the Best Shorts for Thin Legs?

Fit is the most influential factor when selecting the best shorts for thin legs. Shorts that are too tight emphasize thinness, while excessively loose styles may overwhelm the body frame.

A tailored-but-not-tight fit creates visual structure. Slight room in the leg opening allows fabric to drape naturally, giving the illusion of fuller legs. Well-designed shorts often follow the body line without clinging, which is essential for slim-leg styling.

Professionally engineered fits—such as structured casual shorts developed by brands like RE&X—demonstrate how balance between comfort and form can subtly enhance leg appearance without exaggeration.

How Does Length Affect Proportion for Thin Legs?

Length plays a critical role in determining how legs are perceived. The best shorts for thin legs usually avoid extreme lengths.

Mid-thigh shorts help shorten the visible leg line slightly, creating a more balanced proportion. Shorts that end just above the knee may make legs appear slimmer and longer, which can sometimes emphasize thinness.

Designers often recommend experimenting within a 2–3 inch range above the knee to find the most flattering cutoff point. This length visually widens the leg area while maintaining a clean, modern silhouette.

What Fabrics Work Best for Making Thin Legs Look Fuller?

Fabric choice can dramatically change how shorts interact with the body. Lightweight, clingy fabrics tend to follow the leg too closely, while structured fabrics add shape.

The best shorts for thin legs often use medium-weight materials such as twill, canvas, textured cotton, or blended fabrics with slight stiffness. These materials hold their form and prevent excessive draping.

Eco-conscious textile development—such as structured sustainable fabrics increasingly used across the industry, including by RE&X—shows how material engineering contributes not only to comfort, but also to visual balance.

Can Pocket Design Improve the Look of Thin Legs?

Yes, pocket placement and size significantly affect how shorts look on slim legs. Flat, minimal pockets may emphasize narrowness, while well-positioned pockets add volume and structure.

Side pockets with subtle depth, flap pockets, or utility-inspired designs help widen the visual profile of the thighs. Even back pocket positioning can influence perceived proportions.

From a garment construction perspective, pockets act as architectural elements that guide the eye and redistribute visual weight across the shorts.

How Do Colors and Patterns Influence the Best Shorts for Thin Legs?

Color theory plays an important role in styling thin legs. Light colors reflect more light and visually expand surfaces, making them ideal for creating a fuller appearance.

Patterns such as horizontal stripes, checks, textured weaves, or subtle prints help break up long vertical lines. Solid dark colors, while slimming, may accentuate thinness when used alone.

Stylists often recommend combining lighter shorts with darker tops to shift focus downward, reinforcing balance and drawing attention to leg structure.

Are Cuffed Shorts Better for Slim Legs?

Cuffed hems are a highly effective design feature for thin legs. A cuff creates a horizontal break at the hemline, which visually widens the lower leg.

The best shorts for thin legs often include subtle cuffs—neither too thick nor too rigid. This small design element adds weight at the bottom of the shorts, improving proportion without adding bulk.

From a tailoring perspective, cuffs also help stabilize the garment’s shape during movement, maintaining a polished appearance throughout wear.

How Does Rise and Waist Structure Affect Leg Appearance?

Rise length influences where the leg visually begins. Low-rise shorts can elongate the leg excessively, while mid-rise designs create more balanced proportions.

Mid-rise shorts help anchor the torso and distribute attention evenly between upper and lower body. Structured waistbands also provide a clean transition point that enhances overall silhouette.

Professionally fitted waist construction ensures shorts sit correctly without pulling fabric downward, which could otherwise emphasize slimness in the legs.

Can Styling Choices Enhance the Best Shorts for Thin Legs?

Styling complements garment design. Footwear, tops, and layering all influence how shorts appear on thin legs.

Chunkier sneakers, loafers, or boots add visual weight to the lower body. Slightly oversized tops or textured shirts help balance slim legs by shifting volume upward and outward.

These principles are widely applied in contemporary menswear and womenswear, demonstrating that styling strategy is just as important as choosing the best shorts for thin legs themselves.

Why Is Confidence an Overlooked Factor in Wearing Shorts with Thin Legs?

Beyond design and fit, confidence significantly affects how clothing is perceived. When wearers understand why certain shorts work for their body type, they naturally project assurance.

The best shorts for thin legs are those that align with both physical proportions and personal comfort. Feeling at ease in a garment enhances posture, movement, and overall presentation.

Fashion professionals emphasize that informed choices—rather than trend chasing—lead to timeless and confident style outcomes.

How Can Professional Design Philosophy Improve Everyday Shorts Selection?

Modern apparel design integrates aesthetics, ergonomics, and sustainability. Brands rooted in thoughtful design philosophy focus on balance, durability, and user experience rather than short-term trends.

This approach helps consumers identify the best shorts for thin legs by prioritizing structure, proportion, and material performance. Timeless design ensures versatility across seasons and settings.

By applying professional design principles, individuals can build wardrobes that enhance their natural features while remaining practical and refined.

Conclusion

Learning how to make shorts look better on thin legs is a matter of understanding proportion, structure, and design logic. By focusing on fit, fabric, length, and thoughtful details, anyone can confidently choose the best shorts for thin legs and achieve a balanced, stylish appearance grounded in professional fashion knowledge.