For lighting technology, the evolution of LED round high bay lights has been nothing short of revolutionary. As advancements continue to push the boundaries of efficiency and performance, one area that stands out prominently is the significant impact on the lifespan of these lighting fixtures. Here Alite lighting will find the ways in which technological progress contributes to the extended longevity of LED round high bay lights.

1. Solid-State Lighting (SSL) Technology: The shift from traditional lighting sources to LEDs marked a paradigm shift in the lighting industry. LED round high bay lights leverage Solid-State Lighting (SSL) technology, where light is emitted from a solid object—the semiconductor diode. Unlike traditional bulbs with filaments that degrade over time, the solid-state nature of LEDs inherently lends itself to a longer operational life. Technological improvements in SSL have further refined this aspect, ensuring the longevity of round high bay lights.

2. Advanced Thermal Management: Heat is a critical factor affecting the performance and lifespan of LED lights. Advancements in thermal management technology play a pivotal role in maintaining optimal operating temperatures. Cutting-edge designs incorporate heat sinks, advanced cooling systems, and superior materials to dissipate heat efficiently. This results in LED round high bay lights that can withstand higher temperatures, reducing the stress on internal components and contributing to an extended lifespan.

3. Quality of Materials: Technological progress extends beyond just the internal workings of LED round high bay lights; it encompasses the quality of materials used in their construction. The selection of high-grade materials, including robust housings and durable components, ensures resistance to environmental factors such as moisture, dust, and corrosive substances. These advancements enhance the durability of LED round high bay lights, allowing them to withstand harsh conditions and maintain optimal performance over an extended period.

4. Smart Controls and Dimming Technologies: The integration of smart controls and dimming technologies not only enhances energy efficiency but also contributes to the prolonged lifespan of LED round high bay lights. These intelligent systems allow for precise control over the light output, reducing the stress on the components during periods of lower demand. Dimming capabilities also contribute to thermal management, as lower light levels generate less heat, ultimately preserving the longevity of the LED fixtures.

5. Quality of Electronics: Advancements in electronics, particularly in power supplies and drivers, have a direct impact on the reliability of LED round high bay lights. High-quality components and sophisticated circuitry contribute to stable voltage regulation, protecting the LEDs from voltage fluctuations and power surges. This technological refinement ensures a consistent and reliable performance, adding to the overall lifespan of the lighting fixtures.

The lifespan of LED round high bay lights is intricately tied to the relentless march of technological progress. From the foundational shift to Solid-State Lighting to the integration of advanced thermal management, quality materials, smart controls, and high-grade electronics, each technological advancement plays a crucial role in enhancing the durability and longevity of these lighting solutions. As businesses and industries increasingly adopt LED round high bay lights, the continuous evolution of technology promises not only improved performance but also a sustainable and enduring lighting solution for the future.

What role do smart controls and sensors play in enhancing the functionality of round high bay led lighting systems?

For industrial lighting, round high bay LED lighting systems have emerged as a beacon of efficiency, providing powerful illumination for large spaces. However, what elevates these lighting solutions to a new level of sophistication is the integration of smart controls and sensors. Now Alite Lighting will share the pivotal role that these technologies play in enhancing the functionality of round high bay LED lighting systems.

1. Precision Illumination: Smart controls and sensors empower round high bay LED lighting systems with the ability to deliver precision illumination. By leveraging occupancy sensors, these lighting fixtures can detect the presence or absence of individuals within a space. This dynamic adjustment ensures that illumination is optimized only where and when it is needed, leading to significant energy savings. The result is not just efficient lighting but a testament to the commitment to sustainability in industrial settings.

2. Adaptive Brightness: The adaptive brightness feature facilitated by smart controls allows round high bay LED lights to respond intelligently to the ambient light levels. When natural light is available, the system can automatically dim the artificial lighting to maintain an optimal brightness level, reducing energy consumption without compromising visibility. This adaptive capability ensures a comfortable and well-lit environment while maximizing energy efficiency.

3. Customizable Lighting Scenes: Smart controls enable the creation of customizable lighting scenes tailored to specific operational needs. Whether it's a manufacturing floor, warehouse, or commercial space, round high bay LED lighting systems can be programmed to adjust color temperature, intensity, and distribution patterns. This adaptability enhances productivity, creates specific atmospheres, and contributes to the overall well-being of individuals working in these environments.

4. Energy Efficiency and Cost Savings: The integration of smart controls and sensors significantly contributes to energy efficiency and, consequently, cost savings. By automatically adjusting lighting levels based on occupancy and ambient conditions, round high bay LED lighting systems reduce unnecessary energy consumption. This not only aligns with sustainability goals but also results in tangible financial benefits for businesses through lower energy bills and decreased maintenance costs.

5. Remote Monitoring and Management: Smart controls provide the convenience of remote monitoring and management of round high bay LED lighting systems. Facility managers can access real-time data on energy consumption, system health, and performance metrics. This proactive approach allows for timely maintenance, addressing issues before they escalate, and ensuring a reliable and long-lasting lighting infrastructure.

6. Integration with Building Management Systems (BMS): The compatibility of round high bay LED lighting systems with building management systems enhances overall operational efficiency. Smart controls can seamlessly integrate with existing BMS platforms, offering a centralized approach to monitor and control various building functions. This integration promotes a holistic approach to energy management, allowing businesses to optimize resource usage across multiple systems.

7. Enhanced Safety and Security: Occupancy sensors play a crucial role in enhancing safety and security within industrial spaces. In addition to optimizing lighting based on occupancy, these sensors can be integrated with security systems to trigger specific lighting responses in emergency situations. This not only ensures the safety of occupants but also aids security personnel in responding effectively to unforeseen events.

The incorporation of smart controls and sensors transforms round high bay LED lighting systems into intelligent, adaptive, and efficient solutions. The marriage of cutting-edge technology with powerful illumination not only meets the demands of modern industrial environments but also sets the stage for a future where lighting is not just a utility but a strategic asset in achieving sustainability and operational excellence. As businesses navigate the path toward a more connected and efficient future, the role of smart controls and sensors in round high bay LED lighting systems becomes increasingly indispensable.

Here are some manufacturering options for you:

Office wood door,

Faucet design,

LED light manufacturer,

Coffee grinder,

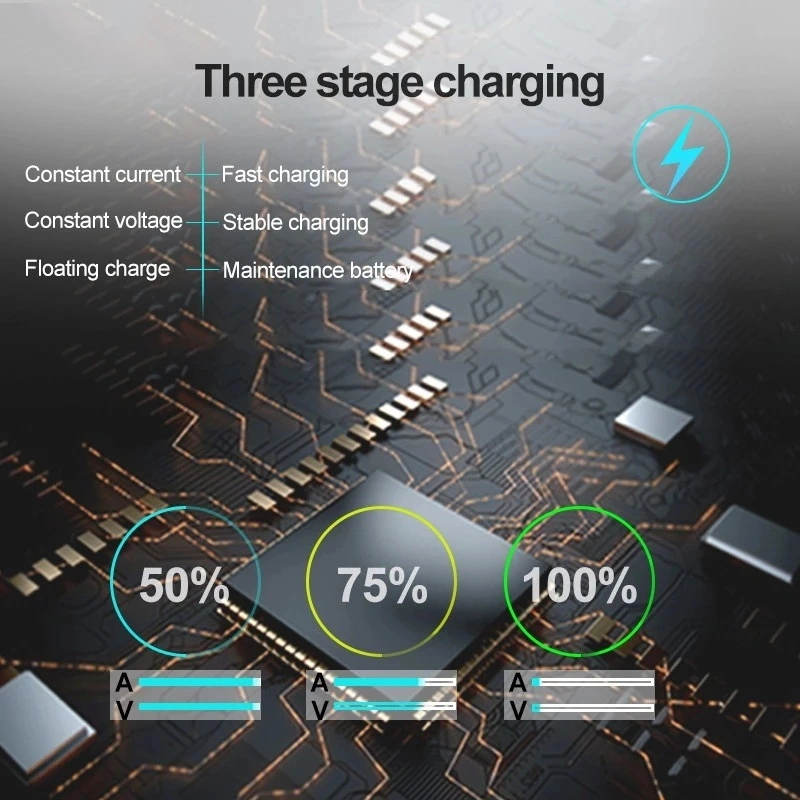

Car battery charger,

Wheel rims for car